Specification

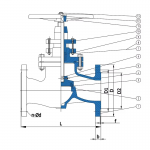

TIANYU Ductile Iron Flange Globe Valve: International Standard-Compliant Industrial Flow Control Solution

I. Product Overview

II. Core Technical Parameters

-

Specifications & Operating Range

- Nominal Diameter: DN50/80/100/150/200/250/300/400/500/600/800/1000/1200 (2″-48″)

- Pressure Class: PN10 (1.0MPa), PN16 (1.6MPa) (compliant with BS EN 1092-1 flanges)

- Temperature Range: -10℃~80℃ (standard), -20℃~120℃ (optional special seals)

- Media: Water, sewage, non-corrosive oils, air

-

Materials & Sealing System

- Body/Bonnet: QT450-10 ductile iron (tensile strength ≥450MPa, elongation ≥10%), HT250 gray cast iron (HB200-240)

- Disc/Seat: Ductile iron metal seal (Ra≤1.6μm), optional NBR/EPDM soft seal (leakage rate ≤0.1%)

- Connections: Flanged (RF face, BS EN 1092-1/ANSI B16.5), female threaded (NPT, API 5B)

- Actuation: Manual (handwheel/lever, operating torque ≤200N·m@DN200)

-

Certifications

- Quality System: ISO 9001:2015

- Product Certifications: CE-PED 2014/68/EU, WRAS (UK drinking water), ACS (French sanitary standard)

Product Overview

III. Structural Design & Technical Features

-

International Standard Compliance

- Body length meets ANSI B16.10, flange dimensions compatible with BS EN 1092-1 and GB/T 9113 for global projects.

- Ergonomic handwheel design: levers for DN≤150, gear-reduced handwheels for DN≥200 to minimize operating force.

-

Durability Optimization

- Ductile iron body annealed at 920℃ to eliminate casting stress, fatigue resistance 30% higher than common cast iron.

- Stem made of 2Cr13 stainless steel (HRC30-35), chrome-plated (≥25μm) for corrosion and wear resistance.

-

Enhanced Sealing Performance

- Wedge disc with 5° tapered seat self-seals via medium pressure, sealing specific pressure ≥15MPa.

- Packing uses V-type PTFE + flexible graphite, gland bolts adjustable online for zero external leakage (≤1×10⁻⁶cc/s).

IV. Manufacturing Processes & Quality Control

-

Precision Casting Flow

- Lost foam casting process, blank dimension tolerance ≤±0.8mm, 100% magnetic particle inspection (MPI) for surface cracks.

- Ductile iron parts low-temperature annealed (550℃×2h), graphite morphology controlled to GB/T 1348 Grade Ⅱ+.

-

High-Precision Machining

- Seat sealing surface CNC lapped to flatness ≤0.01mm, red lead test contact rate ≥85%.

- Stem straightness ≤0.02mm/m, coaxiality with packing ≤0.05mm for smooth operation.

-

3D Quality Inspection

- Hydrostatic test: 1.5x working pressure (2.4MPa for PN16) held 30min, 1.1x sealing pressure—zero leakage.

- Material traceability: Spectral analysis per heat (C/Si/Mn deviation ≤0.05%), provided with Material Test Reports (MTR).

- Life test: 100,000 cycles without sealing degradation (GB/T 13932).

Valve Details

V. Core Product Advantages

-

Multi-Standard Compatibility

- Compliant with BS5152, ANSI B16.10, CE-PED for global project bidding.

- Flanged sizes DN50-DN1200 replace imported valves, reducing procurement costs.

-

Full-Scenario Adaptability

- Municipal water supply: WRAS/ACS certified for drinking water safety, 8-year leak-free operation at -10℃~60℃.

- Building water systems: DN50-DN300 suits high-rise risers, manual operation for emergency cutoff.

- Industrial circulating water: Ductile iron resists chloride (Cl⁻≤2000ppm), erosion life >5 years in cooling networks.

-

Maintenance Cost Optimization

- Replaceable seat design shortens on-site maintenance by 40%, reduces costs by 50%.

- Maintenance-free cycle reaches 5 years or 100,000 operations, 20% more reliable than similar products.

Application

VI. Application Fields & Cases

- Urban waterworks: DN600 PN16 ductile iron valve in main transmission pipe, WRAS certified, 3-year leak-free operation meeting GB 5749 standards.

- Commercial complex: DN150 PN10 gray cast iron valve in fire sprinkler system, manual quick cutoff meets EN 15019 fire standards.

- Industrial wastewater plant: DN300 PN16 valve controls neutral sewage (pH 6-9), ductile iron resists impurity impact, annual wear ≤0.2mm.

VII. Installation & Maintenance Guide

-

Installation Notes

- Align media flow with body arrow; mount horizontally with handwheel upward, vertically with stem upright.

- Torque flange bolts diagonally in three steps (BS EN 1514-3); DN≥300 requires supports to reduce pipeline stress.

-

Routine Maintenance

- Check packing gland tightness quarterly; tighten bolts evenly (torque increase ≤10%) for leakage.

- Inspect anti-corrosion coating annually (thickness ≥100μm), repair with epoxy paint.

-

Troubleshooting

- Minor seat wear repairable by lapping (800+ grit abrasive); replace seat assembly for severe wear.

- Disassemble and clean packing for stem jamming, apply molybdenum disulfide grease (120℃ resistance).

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025