Specification

1. We are professional manufacturer of instrument valves and tube fittings;

2. Superior quality and competitive price;

3. In stock, fast delivery.

Maximum working pressure: 10000 psi (688bar)

Working temperature: -54 to +648 C

Orifice: from 1/8 in. to 1 in.

Flange connections in accordance with ASME B16.5 RF and RTJ

NPT connections in accordance with B1.20.1

Antiblowout ball valve stems and nonrotating seat tips

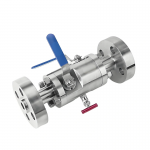

Integral Double Block and Bleed Valves , Stainless Steel body

Product Overview

-

Design Standards and Performance Specifications

- Design Standards: The design of this valve strictly adheres to international authoritative standards, such as the American Society of Mechanical Engineers (ASME) standards, ensuring its universality and reliability worldwide. It also refers to relevant standards in the oil and gas industry to meet the requirements for use in high – pressure and high – risk environments.

- Performance Specifications: It has a pressure – bearing capacity of up to 10000psi, enabling it to operate stably in extreme high – pressure environments. The sealing performance is excellent, effectively preventing medium leakage and ensuring the safety of the production process. The valve is flexible to operate, and the manual operating mechanism is designed in line with ergonomic principles, allowing for easy opening, closing, and opening – degree adjustment of the valve even in high – pressure environments.

-

Product Parameter Characteristics

- Material: The main body is made of high – quality stainless steel, such as 316L stainless steel. This material has excellent corrosion resistance and high strength, enabling it to maintain stable performance in harsh chemical environments and under high – pressure conditions.

- Pressure Rating: The pressure rating is 10000psi, meeting the requirements for ultra – high – pressure valves in fields such as deep – sea oil extraction and high – pressure chemical industry.

- Connection Methods: Multiple connection methods are provided, including threaded connection and flange connection. Threaded connection is suitable for small – diameter pipelines and is convenient for installation. Flange connection is suitable for large – diameter or high – pressure pipelines, offering a firm connection and good sealing performance.

- Operation Method: It adopts a manual operation method. Operators can accurately control the valve opening according to actual needs, achieving fine adjustment of fluid flow and pressure.

-

Manufacturing Process

- Casting Process: The valve body is manufactured using a precision casting process. In the high – temperature molten state, the stainless – steel material is precisely cast. By strictly controlling the casting temperature, speed, and cooling process, the internal structure of the valve body is ensured to be dense and uniform, free from defects such as pores and sand holes, thus guaranteeing the high strength and pressure resistance of the valve body.

- Machining: After casting, the valve body undergoes multiple machining processes. High – precision CNC machining equipment is used to finely process key parts such as valve seats and valve cores. The machining accuracy of the valve seat sealing surface can reach the micron level to ensure the high – precision sealing performance of the valve.

- Surface Treatment: To further enhance the corrosion resistance and wear resistance of the valve, special surface treatment is carried out on the valve, such as chrome plating. The chrome – plated layer can not only effectively resist the erosion of chemical media but also improve the hardness and smoothness of the valve surface, reducing the wear of internal components by the fluid.

- Assembly and Testing: During the assembly process, operations are carried out strictly in accordance with the process requirements to ensure that each component is installed in place and fits precisely. After assembly, a comprehensive performance test is carried out on the valve, including pressure testing, sealing testing, and operation testing. During the pressure test, the valve is placed in an environment with a pressure exceeding the rated pressure to detect whether it can withstand high pressure without deformation or leakage. The sealing test uses specific media to detect the sealing performance of the valve under different pressures. The operation test ensures that the manual operating mechanism of the valve is flexible and reliable.

Valve Details

-

Industrial Applications

- Oil and Gas Industry: It is widely used in the exploration, transportation, and processing of oil and gas. For example, on deep – sea oil – drilling platforms, this valve can be used to control the oil and gas flow at the wellhead, withstanding the test of the deep – sea high – pressure environment. In long – distance natural gas transportation pipelines, it is used to cut off or adjust the gas flow, ensuring the safe and stable operation of the pipeline system.

- Chemical Industry: It is suitable for controlling the feeding and discharging of high – pressure reaction kettles in chemical production, as well as regulating the flow of high – pressure fluid transportation pipelines. Since chemical production often involves corrosive media, the stainless – steel material and good sealing performance of the valve can effectively prevent medium leakage and ensure production safety.

- Energy Industry: It plays an important role in some high – pressure energy production and transmission links, such as underground coal gasification and fluid control in high – voltage power transmission support.

Application

-

Advantages

- Ultra – High Pressure – Bearing Capacity: The pressure – bearing capacity of 10000psi enables it to work reliably under extreme high – pressure working conditions, providing a solid guarantee for high – pressure industrial production.

- Excellent Corrosion Resistance: The stainless – steel material and special surface treatment process endow the valve with outstanding corrosion resistance. It can be used for a long time in various corrosive media, reducing equipment maintenance and replacement costs.

- Precise Operation Control: The manual operation method gives operators direct and precise control ability. They can accurately adjust the valve opening according to actual production needs, meeting the strict requirements of different processes for fluid flow and pressure.

- High Reliability: Strict design standards, advanced manufacturing processes, and comprehensive performance tests ensure that the valve can operate stably for a long time under various complex and harsh working conditions, reducing the risk of failures in the production process and improving production efficiency.

- Customized Service: As a professional valve manufacturer, TianYu is well aware that different customers have unique needs in industrial applications. It can provide customized services according to specific customer requirements, such as special pressure ratings, materials, connection methods, or operating mechanisms, and tailor – make valve products that best suit the industrial production needs of customers.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025