Specification

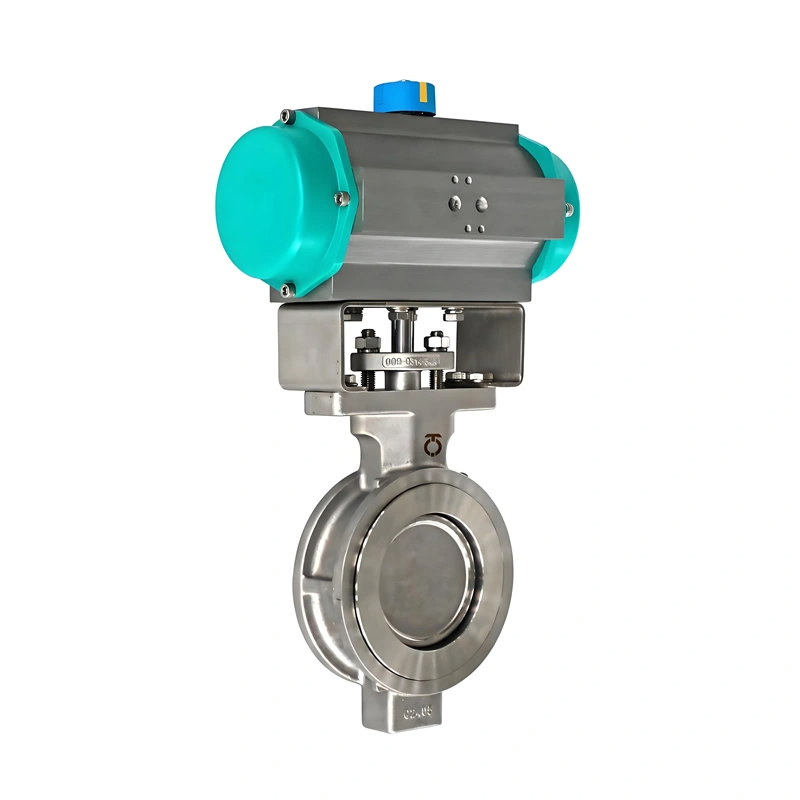

TIANYU Stainless Steel Pneumatic Double-Offset Wafer-Type Butterfly Valve: Efficient Solution for Industrial Fluid Control

I. Product Overview

II. Core Features: Revolutionary Breakthrough of Double-Offset Technology

-

Double-Offset Structural Design

- Eccentric Principle: The stem axis deviates from both the seat centerline and the disc centerline, forming double offsets. This design enables the disc to disengage from the seat rapidly when opening, reducing friction and wear by 60% compared to single-offset structures.

- Seal Enhancement: When closed, the disc and seat form a three-dimensional seal pair. Combined with elastic seal materials like EPDM/NBR/PTFE, it achieves bubble-tight sealing (leakage ≤0.01% of rated flow, compliant with API 598 standards).

- Torque Optimization: The double-offset design reduces opening/closing torque by 40%, with pneumatic actuation torque ≤150N·m for DN300, suitable for low-power air supply systems.

-

High-Efficiency Pneumatic Actuation

- Actuator Configuration: Equipped with double-acting/single-acting pneumatic piston actuators, response time ≤0.8 seconds (DN100), supporting 4~6bar air pressure.

- Control Integration: Optional accessories include positioners, solenoid valves, and limit switches, enabling 4~20mA analog regulation or on/off control, compatible with DCS/PLC systems.

- Safety Design: Single-acting actuators feature spring return, automatically resetting to a safe position (open/close optional) in case of air supply failure.

-

Full Operational Condition Adaptability of Stainless Steel

- Material System: The valve body uses austenitic stainless steels like CF8 (304) and CF8M (316), with tensile strength ≥520MPa and 8x higher chloride corrosion resistance than carbon steel.

- Surface Treatment: The inner wall is electropolished (Ra≤0.8μm), and the outer surface is sandblasted and passivated, passing salt spray tests ≥1000 hours without corrosion.

- Temperature Resistance: Maintains impact toughness ≥27J in -29°C low-temperature environments and structural stability in 120°C high-temperature media.

III. Key Attributes: Technical Parameters and Standard Compliance

| Attribute Category | Specific Parameters |

|---|---|

| Diameter Range | DN80~DN600 (3″~24″), supporting non-standard customization (min DN50, max DN1000) |

| Pressure Rating | ANSI 150Lb (PN10), 300Lb (PN40), compliant with ASME B16.34 pressure-temperature ratings |

| Body Material | CF8 (304), CF8M (316), CF3M (316L), customizable to duplex stainless steel (2205) |

| Seal Material | EPDM (-20°C~120°C), NBR (-40°C~100°C), PTFE (-100°C~260°C), optional food-grade FDA certification |

| Connection Type | Wafer-type, compliant with API 609 and GB/T 12238, reducing installation space by 30% compared to flanged types |

| Actuation Method | Pneumatic (double-acting/single-acting), optional interfaces for electric/hydraulic actuators |

| Manufacturing Standards | Design: API 609, GB/T 12238; Testing: API 598, TSG ZF003; Certifications: CE, TSG A1 grade |

| Suitable Media | Clean water, sewage, crude oil, natural gas, steam, weak acid-base solutions (pH 4~10) |

Product Overview

IV. Manufacturing Processes: Precision Control from Material to Finished Product

-

Stainless Steel Melting and Forming

- Vacuum Refining: Using AOD secondary refining technology, controlling S≤0.03% and P≤0.04%, with Mo content in 316 precisely controlled at 2.0%~3.0%.

- Precision Casting: Silica sol investment casting ensures CT6-level dimensional accuracy, wall thickness deviation ≤±0.5mm, eliminating shrinkage and slag inclusions.

- Heat Treatment: Castings undergo 1050°C solution quenching, grain size ≥Grade 5, passing intergranular corrosion tests (ASTM A262 E method).

-

Precision Machining and Assembly

- 5-Axis Machining: Disc and seat sealing surfaces are CNC ground to surface roughness Ra≤0.4μm, with fit clearance ≤0.02mm.

- Stem Processing: 2Cr13 stainless steel stems are quenched and tempered (HRC28~32) with 0.03~0.05mm chrome plating, enhancing wear resistance by 5 times.

- Actuator Calibration: Each valve undergoes torque testing at 1.1x nominal pressure to ensure actuator-valve matching accuracy ≤±1°.

-

Full-Process Quality Control

- Material Certification: Each batch of stainless steel provides spectral analysis reports and mechanical property data (yield strength ≥205MPa, elongation ≥40%).

- Pressure Testing: Shell tested at 1.5x nominal pressure (e.g., 2.4MPa for PN16) for 15 minutes; seal testing at 1.1x nominal pressure with zero leakage.

- Nondestructive Testing: 100% penetrant testing (PT) for key welds and ultrasonic testing (UT) for valve bodies to ensure no defects ≥1mm equivalent.

Valve Details

V. Product Advantages: Core Competitiveness in Industrial Scenarios

-

Longevity and Low Maintenance

The double-offset structure reduces seal surface wear. Data from a refinery shows TIANYU butterfly valves operating leak-free for 8 years in crude oil pipelines, extending maintenance cycles by 3 times and reducing annual costs by 60%. -

Cost-Efficiency Balance

- Initial Investment: Wafer design saves 30% installation space and material costs compared to flanged valves.

- Operation Cost: Pneumatic actuation consumes 50% less energy than electric drives, and intelligent positioners enable precise flow regulation to reduce energy waste.

- Maintenance Convenience: Modular design shortens actuator-valve disassembly time by 50%, allowing on-site seal replacement without complete valve removal.

-

Customized Solutions

- Condition Adaptation: Optional wear-resistant ceramic-coated discs for particle-containing media, upgraded to 316L + titanium alloy stems for seawater environments.

- Functional Expansion: Explosion-proof actuators (Ex d IIBT4), fire-safe structures (API 607 certified), and anti-static designs (ESD) are available.

- Industry Customization: Food-grade valves feature mirror polishing + FDA-certified seals, while pharmaceutical applications support clean-in-place (CIP) design.

-

Global Service Support

Certified by TSG A1 grade and API 609, products are exported to 50+ countries, performing excellently in Middle Eastern oil fields and Southeast Asian water treatment projects. Offering 7×24-hour technical response, overseas warehouses stock regular accessories for 48-hour on-site delivery.

Application

VI. Application Fields: Full-Industry Fluid Control Coverage

-

Petrochemical Industry

- Flow regulation for overhead oil-gas pipelines in atmospheric-vacuum distillation units.

- Inlet/outlet shut-off for chemical reactors, resistant to organic solvents like methanol and benzene.

-

Water Supply/Drainage and Environmental Protection

- Air volume control for aeration tanks in urban wastewater treatment plants, with EPDM seals resisting ozone corrosion.

- Intake pipelines in seawater desalination plants, with 316L material combating chloride ion erosion.

-

Energy and Power Systems

- Flow distribution for circulating water systems in thermal power plants, stable operation at 120°C.

- Fuel gas pipelines for gas turbines, with quick shut-off valves responding within ≤1 second.

-

Food and Pharmaceutical Sectors

- CIP cleaning systems in beverage production lines, with 304 stainless steel + food-grade seals meeting GMP standards.

- Purified water pipelines in pharmaceutical workshops, with electropolished inner walls preventing media residue.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025