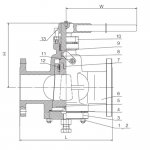

Specification

TIANYU Back Pressure Balanced Lubricated Plug Valve: High-End Industrial Fluid Control Solution

I. Product Overview

II. Key Attribute Parameters

-

Technical Specifications

- Bore Range: DN25~DN350 (1″~14″)

- Pressure Classes: Class 150~Class 900 (PN16~PN150)

- Temperature Range: -29℃~80℃ (standard), customizable to -40℃~180℃

- Design Standards: API 599, API 6D; Flange Standards ASME B16.5; Face-to-Face Dimensions ASME B16.10

- Testing Standard: API 598 (shell strength and seal testing)

-

Material Configuration

- Body/Bonnet: ASTM A216 WCB (cast steel), ASTM A351 CF8/CF8M (stainless steel)

- Plug: ASTM A182 F6a (forged stainless steel), surface hardened (HV≥250)

- Sealing System: Metal hard seal + PTFE auxiliary seal, lubrication passage in brass

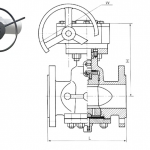

- Actuators: Manual (wrench/handwheel), worm gear, pneumatic, electric (optional)

-

Performance Parameters

- Shell Test Pressure: 3.0/7.5/15.0/22.5MPa for Class 150/300/600/900

- Seal Test Pressure: 2.2/5.5/11.0/16.5MPa (bi-directional zero leakage, API 598 Class VI)

- Operating Torque: ≤120N·m for DN100 Class 150 valve (manual operation)

Product Overview

III. Structural Design & Technical Features

-

Back Pressure Balanced Structure

- A balancing piston at the plug base counteracts axial load using medium pressure, reducing operating torque by 40%~60% and resolving jamming issues in high-pressure applications. The balancing chamber connects to the medium channel, automatically compensating for pressure fluctuations to ensure stable operation in Class 900 systems.

-

Forced Lubrication Sealing System

- A circular lubrication groove between the body and plug injects NLGI 2# lithium-based grease via a high-pressure grease valve, forming a dynamic sealing film (sealing specific pressure ≥12MPa) while minimizing friction wear. The grease isolates media from metal surfaces, preventing scaling and corrosion to extend valve life to 8~10 years.

-

Bi-Directional Flow & Non-Directional Design

- Symmetric flow path eliminates the need to distinguish media direction, offering installation flexibility for bi-directional shut-off scenarios like heat exchanger inlets/outlets and tank connecting pipes. Both flow directions meet API 598 Class VI sealing standards with leakage rate ≤1×10⁻⁹m³/s.

IV. Manufacturing Processes & Quality Control

-

Core Technologies

- Body Casting: Investment casting (lost-wax process) ensures dimensional accuracy CT6 and surface roughness Ra≤12.5μm, with critical areas ultrasonically tested (UT) for no shrinkage defects.

- Plug Machining: CNC lathe precision turning followed by grinding polishes sealing surfaces to flatness ≤0.01mm, with fit clearance to body controlled at 0.05~0.1mm for high-pressure sealing compliance.

- Surface Treatment: Stainless steel components passivated; cast steel parts coated with epoxy resin (thickness ≥100μm), passing 1000-hour salt spray test for marine environments.

-

Quality Certification System

- Certifications: ISO 9001, CE (PED 2014/68/EU), API 6D (optional)

- Testing Procedures:

- 100% shell strength test (1.5× rated pressure, 5-min hold)

- Bi-directional seal test (1.1× rated pressure, 15-min hold)

- Torque fluctuation test (≤15% deviation at ambient temperature)

Valve Details

V. Core Product Advantages

| Advantage Dimension | Technical Details & Application Value |

|---|---|

| High-Pressure Sealing Reliability | Back pressure balance + lubrication design enables 100,000 leak-free cycles in Class 600 systems, tripling service life compared to traditional plug valves. |

| Low Maintenance Cost | Online grease replenishment eliminates disassembly, reducing maintenance time by 70% and downtime losses by 50%. |

| Corrosion Resistance | 316 stainless steel suits chloride-containing media (e.g., seawater, chemical waste) with corrosion rate ≤0.01mm/year. |

| Operation Convenience | Manual torque is 30% lower than similar products; DN200 valves feature force-saving handwheel mechanisms for single-person operation. |

| Total Life Cycle Cost | ≥80,000 cycles (API 598 standard) with 40% lower comprehensive cost than ball valves, ideal for long-term continuous operation. |

Application

VI. Application Fields & Scenarios

-

Oil & Gas Industry

- Wellhead equipment, gathering pipelines (Class 300~Class 900): Resists oil-gas erosion, bi-directional sealing prevents blowout risks;

- LNG storage tank inlets/outlets: Maintains sealing reliability at -29℃ for liquefied natural gas transportation.

-

Chemical & Pharmaceutical Industries

- Reactor feed control: Withstands acid-base media (pH 2~12), 316L stainless steel meets FDA certification;

- Pharmaceutical clean pipelines: Inner wall polished (Ra≤0.8μm), food-grade grease formula complies with cGMP standards.

-

Power & Energy Sector

- Turbine lubrication oil systems: Prevents oil leakage and contamination for generator safety;

- High-pressure steam pipelines (≤16.5MPa): Erosion-resistant design outlasts gate valves by 2~3 times.

-

Municipal & Environmental Engineering

- High-pressure water transmission (e.g., long-distance water projects): Reduces head loss with flow resistance coefficient ≤0.8;

- Wastewater treatment sludge pipelines: Lubrication system prevents fibrous debris jamming, reducing maintenance frequency by 60%.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025