Specification

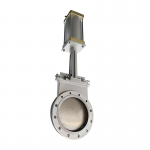

TIANYU Flanged Knife Gate Valve: Industrial Solution for Particulate Media Control

I. Product Overview

II. Core Technical Parameters

-

Specifications & Pressure Classes

- Nominal Diameter: DN50-DN600 (2″-24″), customizable for extra-large sizes

- Pressure Rating: PN10/PN16 (1.0MPa/1.6MPa) for medium-low pressure systems

- Temperature Range: -20℃~120℃ (standard), -40℃~200℃ (high-temperature customization)

-

Materials & Sealing System

- Body/Gate: Ductile iron GGG50 (tensile strength ≥500MPa), 304/316 stainless steel

- Sealing Components: NBR or VITON, leakage rate ≤0.1% (API 598)

- Stem: 2Cr13 stainless steel, chrome-plated (HRC35+ hardness) for corrosion resistance

- Connection: Flanged (ASME B16.5, GB/T 9113), RF face

-

Actuation & Operation

- Manual Drive: Aluminum handwheel, DN100 operating torque ≤120N·m

- Pneumatic/Electric Actuation: Optional, response time ≤1 second

- Protection Grade: IP65 (body), Ex d IIB T4 (explosion-proof for electric models)

Product Overview

III. Structural Design & Technical Features

- **Knife Gate Flow Optimization

- Blade-shaped gate design cuts through fibrous media (e.g., paper pulp, sewage fabrics) to prevent tangling.

- Straight-through flow path reduces flow resistance by 25% compared to conventional gate valves, suitable for high-viscosity fluids.

- **Elastic Sealing Reliability

- Lip-shaped elastic seat design automatically compensates sealing specific pressure (≥8MPa) via medium pressure.

- Double-sealing surface grinding precision ≤0.03mm flatness, verified by red lead powder testing.

- **Anti-Jamming Details

- Gate guide groove tolerance ≤0.1mm ensures precise lifting, avoiding particle jamming.

- Inclined body bottom design prevents medium sedimentation, improving self-cleaning by 30%.

IV. Manufacturing Processes & Quality Control

- **Precision Casting

- Ductile iron castings use lost foam process with graphite spheroidization grade ≥2, eliminating shrinkage defects.

- Stainless steel parts undergo 1050℃ solution treatment, grain size ≥Grade 5 for excellent intergranular corrosion resistance.

- **High-Precision Machining

- Gate blade processed by 5-axis CNC grinder, edge roughness Ra≤1.6μm.

- Stem thread precision reaches 6g grade, fit clearance ≤0.05mm.

- **3D Quality Inspection

- Hydrostatic test: 1.5x working pressure for shell (30min hold), 1.1x for sealing (zero leakage).

- Spectral analysis: Element deviation ≤0.05% per heat to ensure material consistency.

- NDT: 100% ultrasonic testing (UT), compliant with GB/T 2970 Grade III.

Valve Details

V. Core Product Advantages

- **Multi-Scenario Adaptability

- Wastewater treatment: Resists sand abrasion, gate cuts fibrous impurities in sewage for DN≤300 pipes.

- Papermaking: VITON seals withstand 120℃ cooking liquor, service life >8 years.

- Food processing: 316 stainless steel + FDA-certified seals meet 3-A sanitary standards for slurry transport.

- **Full-Life Cost Optimization

- Replaceable seat design reduces on-site maintenance costs by 50%.

- Maintenance-free cycle reaches 10,000 operations, doubling similar products.

- **Global Certification Support

- CE/PED 2014/68/EU certified, China Special Equipment Manufacturing License (TS).

- Provides Material Test Reports (MTR) and pressure test certificates (ISO 5208).

Application

VI. Application Fields & Cases

- Municipal wastewater plant: DN400 PN10 knife gate valve in post-grating pipes, 3-year jam-free operation for fibrous sewage.

- Papermaking pulping workshop: DN200 PN16 stainless steel valve controls wood pulp, VITON seals maintain zero leakage at 80℃.

- Food starch plant: DN100 316 stainless steel valve in corn slurry pipes, electropolished (Ra≤0.8μm) to meet FDA standards.

VII. Customization Services

- **Material Upgrades

- Duplex stainless steel (2205): Resists Cl- ≤20,000ppm for seawater treatment.

- Hastelloy C-276: Withstands strong acid/alkali (pH 1-14) media.

- **Functional Enhancements

- Anti-static design: Conductive spring between gate and body, ground resistance ≤10Ω.

- Fire-safe structure: Complies with API 6FA, maintains sealing for 30min during fires.

- **Special Interface Customization

- Wafer connection: For space-constrained scenarios, meets API 609.

- Sanitary clamp connection: DN15-DN100, complies with ISO 2852.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025