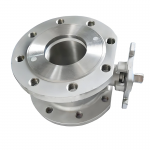

Product Overview

TIANYU DN20 Thin Type Flanged V-Type Stainless Steel Ball Valve: Compact and Efficient Solution for Industrial Fluid Control

I. Technical Overview

II. Core Product Features

(A) Compact Thin Structure Design

- Space Optimization: The valve body thickness is only 60% of traditional flanged ball valves, saving 35% installation space, ideal for 夹层 pipelines (sandwich pipelines) and compact equipment;

- Low Flow Resistance: Full bore design with resistance coefficient ≤0.8, improving media flow efficiency by 20%, saving ~1,200kWh annual pumping energy;

- Quick Operation: 90° rotation for full open/close, manual operation torque ≤50N·m, suitable for emergency shut-off.

(B) Advantages of V-Type Sealing System

| Component | Material | Performance Advantages |

|---|---|---|

| Body/Ball | 304 stainless steel (06Cr19Ni10) | Tensile strength ≥515MPa, chloride corrosion resistance for weak acidic media |

| Seat | PTFE + carbon fiber reinforced | -20℃~232℃ temperature resistance, friction coefficient ≤0.05, self-lubricating maintenance-free |

| Sealing Structure | Double seat spring preloading | Bidirectional leakage rate ≤1×10⁻¹⁰m³/s, compliant with API 598 Class IV |

| Stem | 17-4PH precipitation hardening SS | Blowout-proof design (ASME B16.34), hardness HRC30-35 |

(C) Corrosion-Resistant Material System

III. Key Technical Attributes

| Parameter Category | Specifications | Expansion Options |

|---|---|---|

| Size Range | DN15~DN100 (1/2″~4″) | Custom DN150 thin type (negotiable) |

| Pressure Rating | PN16 (1.6MPa) | PN25/PN40 high pressure (up to 4.0MPa) |

| Applicable Media | Water, natural gas, weak acidic liquids (pH4-10) | 316L stainless steel for strong corrosion media (e.g., 3% nitric acid) |

| Connection Type | Thin flanged (ISO 7005-2) | Welded/threaded (NPT/BSP) customization |

| Compliance Standards | GB/T 12237, ISO 9001:2015 | CE, API 6D certification (optional) |

IV. Manufacturing Processes & QC

(A) Precision Forging & Machining

- Body Forming:

- 4000-ton friction press forging of 304 stainless steel billet, forging ratio ≥4:1, ultrasonic testing (UT) for internal defects (sensitivity ≥Φ1.2mm);

- Thin flange machined by CNC lathe with parallelism error ≤0.05mm for sealing surface precision.

- Core Processing:

- V-shape cut by 5-axis CNC milling, angle error ≤±0.5°, surface roughness Ra≤0.8μm;

- Ball and seat paired grinding with fit gap ≤0.01mm for zero leakage.

- Surface Treatment:

- Body passivated (ASTM A967), 1000-hour salt spray test without corrosion;

- Electropolishing (Ra≤0.4μm) for food-grade applications, compliant with FDA 21 CFR 177.2600.

(B) End-to-End Quality Control

- Pressure Test: 1.5x nominal pressure (2.4MPa) hydrostatic test for 30 minutes without leakage;

- Air Tightness Test: 1.1x pressure (1.76MPa) helium detection, leakage rate ≤5×10⁻⁹Pa·m³/s;

- Life Test: Sampled for 50,000 cycles with ≥95% sealing retention (industry standard: 30,000 cycles).

Valve Details

VI. TIANYU Customization Advantages

- Technical Customization: Non-standard flanges (DIN/GOST/JIS), high-temperature (350℃)/low-temperature (-46℃) types, explosion-proof handles (ATEX certification), with 3D modeling and fluid simulation;

- Flexible Delivery: 31-day standard lead time, 15-day expedited for small batches (MOQ 100 units), 24-hour emergency channel;

- Global Service Network: 12-month warranty, 24/7 response from 3 major service centers (APAC/Europe/NA), 48-hour airfreight for spare parts, with installation training and digital manuals.

Application

V. Application Scenarios

- Chemical Pipeline: On/off control for weak acidic media (e.g., 10% citric acid), 304 stainless steel ensures ≥5-year leak-free service;

- Building Water Systems: Flow regulation in high-rise buildings, thin design saves ceiling space, PN16 suits municipal water supply;

- Food & Beverage: Juice/drinking water pipeline control, electropolished body meets 3A sanitary standards, preventing media contamination;

- Gas Systems: Safety shut-off for natural gas inlet pipelines, V-type seal prevents 微量泄漏 (trace leakage), ensuring safety.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025