Specification

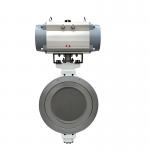

TIANYU High-Performance Wafer Double-Offset Butterfly Valve: Precision Solution for Industrial Fluid Control

I. Product Overview

II. Core Features: Double-Offset Technology and Material Innovation

-

Double-Offset Structural Design

- Eccentric Principle: The stem axis deviates from both the seat centerline and disc center, forming double offsets. This design allows the disc to disengage from the seat rapidly when opening, reducing seal surface friction by 70% compared to ordinary butterfly valves.

- Sealing Performance: The 3D offset structure creates a line seal between the disc and seat. Paired with elastic seals (EPDM, NBR, or PTFE), it achieves ANSI FCI 70-2 Class VI (bubble-tight) sealing.

- Torque Optimization: The double-offset design significantly reduces opening/closing torque. The electric actuation torque for DN600 is ≤350N·m, reducing energy consumption by 25% compared to similar products.

-

Material System Optimization

- Body Materials: Carbon steel (WCB) suits conventional industrial scenarios; stainless steel (304/316) offers 8x higher chloride corrosion resistance for seawater or chemical environments; ductile iron (QT450-10), 40% stronger than ordinary cast iron, applies to low-pressure large-diameter pipelines.

- Surface Treatment: The valve body uses epoxy coating (thickness ≥200μm), passing salt spray tests ≥1000 hours without rust, compliant with drinking water standards (WRAS certified).

- Temperature Adaptability: Special material combinations meet requirements for -29°C low-temperature LNG pipelines and 350°C high-temperature steam systems.

-

Intelligent Drive System

- Actuator Configuration: Optional electric (AC220V/380V), pneumatic (4-6bar), or hydraulic actuators. The electric actuator has IP68 protection and Ex d IIBT4 explosion-proof rating.

- Control Modes: Supports on/off type and regulating type (4-20mA analog), with optional smart positioners for PID regulation and ±0.5% accuracy.

- Remote Monitoring: Integrated with Modbus/TCP, Profibus, etc., enabling remote control and status feedback via SCADA systems.

III. Key Attributes: Technical Parameters and Standard Compliance

| Attribute Category | Specific Parameters |

|---|---|

| Diameter Range | DN50-DN1200 (2″-48″), supporting non-standard customization (max DN2000) |

| Pressure Rating | PN10/PN16/PN25/PN40, compliant with EN 1092-1 and ASME B16.5 flange standards |

| Body Material | WCB carbon steel, SS304/316 stainless steel, QT450-10 ductile iron, optional duplex stainless steel (2205) |

| Seal Material | EPDM (-20°C-120°C), NBR (-40°C-100°C), PTFE (-100°C-260°C), metal hard seal (high-temperature type) |

| Connection Type | Wafer-type, compliant with ISO 5752 and GB/T 15188.1 standards |

| Actuation Method | Electric (on/off/regulating), pneumatic (double-acting/single-acting), manual worm gear |

| Manufacturing Standards | Design: API 609, EN 593, GB/T 12238; Testing: API 598, ISO 5208; Certifications: CE, TSG |

| Suitable Media | Clean water, sewage, steam, gas, oil products, weak acid-base solutions (pH 4-10) |

Product Overview

IV. Manufacturing Processes: Precision Control from Material to Finished Product

-

Melting and Forming

- Precision Casting: Carbon steel uses lost foam casting, stainless steel uses investment casting, and ductile iron uses resin sand casting, achieving CT7-level dimensional accuracy and eliminating defects like pores.

- Heat Treatment: Castings undergo normalizing and tempering to eliminate internal stress and improve metallographic structure, with carbon steel hardness controlled at HB120-180.

- Material Testing: Each batch of materials undergoes spectral analysis and mechanical property testing (yield strength ≥205MPa, elongation ≥25%).

-

Precision Machining and Assembly

- CNC Machining: 5-axis 联动 machining centers ensure IT7-level precision for disc and seat seal surfaces, with surface roughness Ra≤0.8μm.

- Stem Treatment: 42CrMo alloy steel stems are quenched and tempered (HRC28-32) with 0.05mm hard chrome plating for 5x wear resistance.

- Assembly Testing: Each valve undergoes 1.5x nominal pressure shell testing and 1.1x seal testing; electric actuators are debugged for 100 cycles without jamming.

-

Quality Inspection System

- Nondestructive Testing: Magnetic particle inspection (MT) for stem surface cracks; ultrasonic testing (UT) for valve body internal defects.

- Performance Testing: KV value (flow coefficient) testing for DN≥600 valves with error ≤±3%.

- Life Verification: 100,000 cycle tests ensure seal wear ≤0.05mm and torque variation ≤5%.

Valve Details

V. Product Advantages: Core Competitiveness in Industrial Scenarios

-

Long Service Life and Low Maintenance

The double-offset structure reduces seal wear. A DN300 butterfly valve in a chemical plant operated for 8 years without seal replacement, reducing maintenance costs by 60% compared to ordinary valves. -

Cost-Effectiveness Optimization

- Initial Investment: Wafer design costs 20% less than flanged valves, with DN600 models offering a price advantage of ¥15,000.

- Installation Cost: 15% lighter weight reduces lifting and foundation costs by 30%.

- Operation Energy Consumption: Electric actuator power is 25% lower than similar products, saving ~8,000 kWh annually (DN600 model).

-

Customized Solutions

- Condition Adaptation: High-temperature graphite seals (≤450°C) for high-temperature conditions; hard alloy seal surfaces for particle-containing media.

- Functional Expansion: Special designs including fire-safe (API 607 certified), cryogenic (-40°C), and explosion-proof (ATEX certified).

- Connection Customization: Supports JIS, ANSI, ASME, etc., with non-standard flanges machined to drawings.

-

Global Service Support

Exported to 40+ countries, with 5 major warehouses in Europe and Southeast Asia for 48-hour emergency response. Offering full lifecycle management, including selection consultation, installation guidance, and fault diagnosis.

Application

VI. Application Fields: Multi-industry Fluid Control Coverage

-

Municipal Water Supply/Drainage

- Flow regulation for urban water main pipes, DN1000 models used in long-distance water transmission projects.

- Aeration systems in wastewater treatment plants, EPDM seals resisting ozone corrosion.

-

Power Industry

- Circulating water systems in thermal power plants, DN800 valves reducing cooling water energy consumption by 12%.

- Nuclear power plant auxiliary pipelines, complying with ASME BPVC Section III nuclear standards.

-

Metallurgy and Mining

- Blast furnace gas pipeline flow control, designed for high pressure difference (≤0.6MPa).

- Mineral slurry transportation in concentrators, wear-resistant coated discs extending service life by 3x.

-

Paper and Chemical Industries

- Cooking liquor pipelines in paper mills, resistant to acid-base (pH 2-12).

- Inlet/outlet of chemical reactors, fast shut-off function ensuring production safety.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025