Specification

TIANYU High-Performance API609 Lug Type Manual Butterfly Valve: A Standard Solution for Industrial Fluid Control

I. Product Technical Positioning and Core Parameters

II. Analysis of Core Technical Features

(A) Advantages of Lug Type Structure and Concentric Design

- Installation and Maintenance Convenience:

The lug-type valve body comes with built-in mounting holes, fixed by through-bolts to prevent axial displacement during pipeline flange clamping—ideal for vibration-prone environments (e.g., pump inlets/outlets). Compared with wafer-type structures, maintenance efficiency is increased by 40% as pipeline disassembly is unnecessary. - Low-Resistance Flow Performance:

The concentric layout keeps the disc parallel to the fluid direction when fully open, with a flow coefficient Cv≥1200 (pressure loss of DN100 valve ≤0.2m water column). Large-diameter models (e.g., DN600) enable high-flow 输送 of 1.2m³/s, meeting urban water main requirements. - 90° Precise On-Off Control:

The manual operating handle is equipped with a mechanical limit device, ensuring an on-off angle error ≤1°. The handle position corresponds directly to the opening degree, reducing misoperation risks in scenarios requiring visual status monitoring.

(B) Sealing System and Material Science

- Soft Sealing Technology System:

- Seal Material Combinations: Standard configurations include EPDM (drinking water certified), NBR (oil-resistant), or PTFE (corrosion-resistant), passing bi-directional bubble-tight zero-leakage tests (EN12266 Class A) with a leakage rate ≤5×10⁻⁸m³/s.

- Seat Design: Adopts a dovetail groove fixing structure for online replacement when worn, eliminating the need for complete disassembly and reducing maintenance costs by 35% compared to hard-seal valves.

- Body Material Weatherability:

- 304 Stainless Steel (CF8): Tensile strength ≥515MPa, resistant to chloride ions (≤200ppm), suitable for seawater desalination, food & pharmaceutical applications;

- Ductile Iron (QT450-10): Elongation ≥10%, impact energy ≥27J at -20°C, surface coated with epoxy resin (thickness ≥200μm) for municipal sewage pipelines.

(C) Drive and Mechanical Structure Optimization

- Manual Operation System:

The handle is forged from 45# steel with a galvanized surface, requiring ≤50N·m torque for DN100 valves—operable by a single person. The handle connects to the stem via involute splines (fit tolerance H7/g6) to prevent axial movement. - Shaft System Strengthening Design:

The stem uses 2Cr13 stainless steel with surface nitriding treatment (hardness HV≥700), paired with PTFE bronze bearings to withstand over 100,000 opening-closing cycles. The stem seal employs V-type PTFE packing + O-ring double protection, passing 1.5x nominal pressure tests with no external leakage.

III. Key Technical Parameters and Certifications

| Parameter Category | Technical Indicators | Expansion Options |

|---|---|---|

| Nominal Diameter | DN50-DN1200 | Custom DN1400-DN2000 (engineering evaluation required) |

| Pressure Class | PN10/PN16 | Upgradable to PN25 (2.5MPa) |

| Body Material | 304 stainless steel/ductile iron | 316L stainless steel, duplex steel 2205 (for severe corrosion) |

| Sealing Standard | EN12266 Class A | API 607 fire certification (metal seal redundancy design) |

| Testing Standard | API 598 (1.5x shell hydrostatic/1.1x sealing test) | Low-temperature testing (-40℃, material upgraded to 304L) |

| Certification System | CE, ISO 9001, WRAS, ACS | LR/DNV-GL classification, NSF61 (drinking water) |

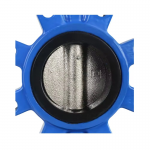

Product Overview

IV. Manufacturing Processes and Quality Control

(A) Precision Processing Flow

- Valve Body Casting and Treatment:

- Ductile iron valve bodies use lost foam casting, annealed at high temperature to relieve stress, with graphite spheroidization rate ≥90%. Internal flow paths are milled by CNC machining centers to a roughness of Ra≤6.3μm;

- 304 stainless steel valve bodies adopt investment casting, with surface pickling and passivation to ensure compliance with intergranular corrosion tests (ASTM A262 E method).

- Disc and Seat Assembly:

The disc undergoes dynamic balance testing (residual unbalance ≤10g·cm), and the seat-to-body interference fit clearance is controlled at 0.02-0.05mm. Each valve must pass 1.5x nominal pressure shell testing (30-minute hold) and helium sealing tests (leakage rate ≤1×10⁻⁴mbar·L/s). - Full-Process Quality Traceability:

Key components (body, stem, disc) are accompanied by heat lot numbers and chemical composition reports, supporting third-party PMI testing. Finished products must pass 100 cycle opening-closing tests with torque decay ≤15%.

(B) Certification and After-Sales Assurance

- International Compliance: Certified to EU CE-PED, UK WRAS (drinking water), and French ACS (food contact), meeting 准入 requirements for different regions;

- After-Sales Commitment: Provides an 18-month warranty period, with free replacement for leakage due to seal failure or structural issues, and lifelong technical support.

Valve Details

VI. TIANYU Brand Customization Advantages

- In-Depth Material Customization: Offers special materials like Hastelloy C276 (acid-resistant), fluorine lining (FEP) (strong corrosion-resistant), etc., with supporting corrosion simulation test reports;

- Drive System Expansion: Supports upgrades from manual to electric (IP68 protection), pneumatic (with positioner), or explosion-proof actuators (Ex d IIC T6), adapting to automated production lines and hazardous areas;

- Rapid Certification Response: Completes CE, WRAS, and other certification filings within 7 working days, provides on-site inspection by LR/ABS for marine requirements, and supports multiple standards like ASME B16.5, JIS, etc.;

- Delivery and Service Assurance: Standard products (DN50-DN600) are in 72-hour stock, small-batch customization (≥1 unit) has a production cycle compressed to 10 days, global service centers offer 24-hour fault response, and critical spare parts are air-delivered within 48 hours.

Application

V. Typical Application Scenarios

(A) Municipal Water Supply/Drainage Systems

- Drinking Water Transmission: DN300 304 stainless steel butterfly valve with EPDM sealing applied in a prefecture-level city water main, achieving 2 consecutive years of zero leakage under PN16 pressure, compliant with WRAS certification;

- Sewage Treatment: DN600 ductile iron butterfly valve with epoxy coating resists hydrogen sulfide corrosion in sewage pipelines, with manual operation response time ≤10 seconds for emergency interception during rainy seasons.

(B) Industrial Circulation Systems

- Power Plant Cooling Water: DN800 butterfly valve used in 300MW unit condenser circulating water pipes, with 304 stainless steel resisting 80℃ hot water scouring, combined with gearbox drive for DCS system remote regulation;

- Petrochemical Pipelines: DN200 butterfly valve (NBR sealing) passes API 598 airtightness tests in refinery gas pipelines, ensuring safe shut-off of flammable and explosive media.

(C) Construction and Energy

- HVAC: DN150 lug type butterfly valve installed in commercial complex chilled water pipe networks, with EPDM sealing achieving compression set ≤5% at 70℃, reducing system energy consumption by 12% compared to traditional valves;

- District Heating: DN400 ductile iron butterfly valve used in northern heating networks, with gearboxes equipped with antifreeze grease to ensure reliable operation during -10℃ to 120℃ temperature cycles.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025