Specification

Duplex Filters in Multi-Media Industrial Filtration: Key Technologies of 304 Stainless Steel/PP Filter Cartridges and Automatic Cleaning Systems

Introduction: The Core Component of Industrial Filtration Systems and Modern Challenges

In today’s industrial environment, filtration technology has become a critical tool for ensuring production efficiency, product quality, and minimal environmental pollution. Particularly in industries such as chemicals, petroleum, food and beverage, pharmaceuticals, and water treatment, the demand for multi-media filtration is growing, driving higher requirements for the reliability, precision, and automation of filtration equipment. Duplex filters, as core components of industrial filtration systems, meet the stringent needs for uninterrupted filtration and efficient cleaning in continuous production processes through their unique design and functionality.

As an innovator in industrial fluid control, TIANYU integrates advanced valve technology with filtration processes to offer a series of duplex filter solutions. These solutions combine the latest advancements in materials science, mechanical engineering, and automation control technology, providing users with high-performance, easy-to-operate, and low-maintenance filtration systems. This article comprehensively explores the working principles, technical features, application areas, and selection criteria of TIANYU duplex filters, serving as a professional reference for engineers and decision-makers.

I. Basic Concepts and System Composition of Duplex Filters

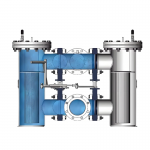

Duplex filters, also known as parallel switching filters, are precision filtration devices consisting of two parallel filter units. This design allows the system to perform filter cleaning or replacement without interrupting operations, significantly enhancing process continuity and reliability. Each filter unit is equipped with independent inlet/outlet valves and control units, enabling seamless switching through well-designed piping layouts.

TIANYU duplex filters are based on a modular design philosophy and redundancy backup concept. The system primarily comprises the following key components:

-

Filtration Units: Typically cylindrical structures housing filter cartridges and support components. Each unit can independently handle the full filtration load, ensuring uninterrupted operation during maintenance.

-

Valve Systems: Include three-way ball valves, stop valves, and automatic drain valves, forming the core of fluid control. These valves work in precise coordination to enable flow path switching, backwash control, and media direction.

-

Filter Cartridges: Available in various materials and precision levels, including 304/316L stainless steel metal cartridges, PP cotton cartridges, PP pleated cartridges, and melt-blown cartridges, meeting needs from coarse to precision filtration.

-

Control Systems: Utilize PLCs (Programmable Logic Controllers) integrated with pressure sensors, timers, and human-machine interfaces (HMIs) for fully automated operation and status monitoring.

-

Structural Framework: Constructed from stainless steel (SUS304/316L), including bases, pipe connectors, and support structures, ensuring corrosion resistance and structural integrity in harsh industrial environments.

This meticulously designed system ensures not only filtration efficiency but also simplifies operation and reduces maintenance complexity. The modular design of TIANYU duplex filters allows users to flexibly configure systems tailored to their specific process requirements.

Product Overview

II. Working Principles and Precision Coordination with Valve Systems

The operation of duplex filters is based on parallel redundancy and differential pressure control. Under normal conditions, fluid enters the system through the inlet pipe and is directed to one of the filter units via a three-way ball valve. As the fluid passes through the cartridge, suspended particles and impurities are captured, while clean fluid exits through the outlet.

When accumulated impurities increase the differential pressure across the filter cartridge, sensors detect this change. Once the preset threshold (typically 0.05–0.1 MPa) is reached, the control system triggers the cleaning cycle. Here, the valve system plays a critical role:

-

Three-Way Ball Valves redirect flow to the parallel filter unit.

-

Drain Valves open automatically to discharge waste during cleaning.

-

Inlet and Outlet Valves coordinate to isolate the unit requiring maintenance.

The backwashing process uses clean fluid reverse flow technology, where clean liquid flows backward through the cartridge to dislodge and remove accumulated debris. This process typically takes only seconds, restoring the cartridge’s filtration capacity before the system resumes normal operation.

TIANYU’s innovation lies in seamlessly integrating industrial valve technology with filtration processes. Its specialized three-way ball valves feature:

-

Low Flow Resistance Design: Optimized flow paths reduce pressure loss and energy consumption.

-

Rapid Actuation: Ensures quick switching between units with minimal process disruption.

-

High-Strength Sealing: Utilizes PTFE or metal seals for leak-free operation.

-

Multiple Actuation Options: Supports manual, pneumatic, or electric operation to suit varying automation needs.

This precise coordination between valves and filtration enhances system reliability and significantly improves cleaning efficiency and cartridge lifespan. Additionally, TIANYU systems offer multiple control strategies, including differential pressure triggering, timed triggering, and manual triggering, to meet diverse application requirements.

III. Application Areas and Adaptability to Multi-Media Processing

The flexibility of duplex filters enables them to adapt to various industrial environments and media types, demonstrating exceptional multi-media processing capabilities. Below is an overview of TIANYU duplex filter applications across industries:

-

Chemicals and Petrochemicals: Used to handle corrosive media like caustic soda, sulfuric acid, and acetic acid. TIANYU offers filter units made of special alloys (e.g., Hastelloy, titanium) and specialized seals for long-term stability in aggressive environments.

-

Water Treatment Systems: Applied in ultrapure water pretreatment, oilfield water injection, and circulating water treatment. These systems effectively remove suspended solids, microorganisms, and particulate matter to protect downstream equipment and membrane separation systems.

-

Food and Beverage Industry: Designed to meet strict hygiene standards, TIANYU provides GMP-compliant sanitary duplex filters with polished surfaces and dead-space-free designs to prevent product contamination. Typical applications include beverage water filtration, dairy processing, and syrup purification.

-

Pharmaceuticals and Biotechnology: Used for filtering pharmaceuticals, process water, and fermentation media. TIANYU offers integrity-testable cartridges and sterile-designed filtration systems to meet cGMP requirements.

-

Electronics and Power Industry: Critical for ultrapure water production and cooling water treatment in microelectronics manufacturing and power generation, protecting equipment and improving product quality.

The table below summarizes key application areas and technical highlights of TIANYU duplex filters:

Table: Applications and Technical Features of TIANYU Duplex Filters

| Application Area | Typical Media | Recommended Cartridge | Filtration Precision | Special Requirements |

|---|---|---|---|---|

| Chemical Processing | Corrosive chemicals, solvents | 316L stainless steel, titanium | 1–50 μm | Corrosion resistance, explosion-proof design |

| Oil & Gas | Injection water, crude oil, slurry | Metal sintered mesh, PP melt-blown | 5–100 μm | High dirt capacity, high-pressure resistance |

| Food & Beverage | Water, syrups, wines, dairy | 316L stainless steel, PP pleated | 0.5–25 μm | Sanitary design, no dead zones |

| Pharma & Biotech | Pharmaceuticals, pure water, fermentation media | 316L stainless steel, PTFE | 0.2–10 μm | Sterile design, sterilizable |

| Electronics | Ultrapure water, chemical reagents | High-purity PP, PVDF | 0.1–5 μm | Low extractables, low metal ions |

| Wastewater Treatment | Industrial wastewater, circulating water | Stainless steel mesh, woven wire | 50–400 μm | High strength, wear resistance |

This broad applicability stems from TIANYU’s modular design and material diversity. Users can select the optimal configuration based on specific media characteristics (e.g., viscosity, corrosiveness, particle content, temperature) to achieve the best filtration efficiency and cost-effectiveness.

IV. Filter Cartridge Selection Strategy: Comparing 304 Stainless Steel vs. PP Cartridges

Filter cartridges, as the core filtering components, directly impact filtration efficiency, operational costs, and system reliability. TIANYU offers various cartridge materials, with 304/316L stainless steel and PP (polypropylene) cartridges being the most common options, each with distinct performance characteristics and suitable applications.

IV.I Technical Features of 304 Stainless Steel Cartridges

Made from high-quality stainless steel wire mesh or sintered stainless steel felt, these cartridges offer:

-

Excellent Mechanical Strength: Withstand high differential pressures and frequent backwashing without deformation or damage.

-

Superior Temperature Resistance: Operate continuously from -80°C to 450°C, suitable for high-temperature processes.

-

Outstanding Chemical Compatibility: Resist corrosion from various chemicals, especially in alternating acid-base environments.

-

Multiple Precision Levels: Range from 1 μm to 100 μm to meet different accuracy requirements.

-

Reusability: Can be reused multiple times via backwashing, offering a long service life.

Stain steel cartridges are ideal for high-temperature, highly corrosive, or frequently backwashed applications, making them the preferred choice in chemicals, petroleum, and pharmaceuticals.

Valve Details

IV.II Technical Advantages of PP Cartridges

Made from polypropylene fibers via melt-blown or pleated processes, PP cartridges provide:

-

High Dirt Holding Capacity: Deep filtration structure traps large amounts of contaminants, extending service cycles.

-

Excellent Chemical Stability: Resist acids, alkalis, and organic solvents.

-

Low Extractables: Do not release impurities into the filtered media, ideal for food and pharmaceutical applications.

-

Cost-Effectiveness: Lower initial investment and replacement costs.

-

Various Structural Forms: Include PP cotton cartridges, PP pleated cartridges, and more.

PP cartridges are particularly suitable for water treatment, food and beverage, and electronic chemicals where high purity and moderate corrosiveness are required.

IV.III Selection Guide and Technical Comparison

To assist users in selecting the appropriate cartridge type, the table below compares key technical parameters of 304 stainless steel and PP cartridges:

Table: Technical Comparison of 304 Stainless Steel vs. PP Cartridges

| Parameter | 304 Stainless Steel Cartridge | PP Cartridge |

|---|---|---|

| Filtration Precision | 1–100 μm | 0.5–100 μm |

| Max. Operating Temp. | 450°C | 80–100°C |

| Pressure Resistance | ≤1.0 MPa | ≤0.6 MPa |

| Chemical Tolerance | Resists acids, alkalis, solvents (except strong oxidizing acids) | Resists acids, alkalis, general chemicals |

| Initial Cost | Higher | Lower |

| Service Life | Long (reusable) | Medium (limited reusability) |

| Applicable Industries | Chemicals, petroleum, pharmaceuticals, high-temperature processes | Water treatment, food & beverage, electronics, general industry |

| Hygiene Rating | Sanitary grade available | Food grade, pharmaceutical grade |

In addition to material selection, users should evaluate filtration precision, dirt capacity, permeability, and structural integrity. TIANYU’s engineering team recommends providing detailed media characteristics (composition, viscosity, particle distribution) and process conditions (temperature, pressure, flow rate) for tailored solutions.

Notably, TIANYU also offers multi-layer composite cartridges and gradient-density cartridges, which combine different materials and precision levels to achieve higher filtration efficiency and longer service life, especially for complex media with high impurity content and wide particle distribution.

V. Advanced Valve Technology and Control Mechanisms in Automatic Cleaning Systems

The trend in modern industrial filtration is toward high automation and intelligence. TIANYU duplex filters exemplify this direction through their automatic cleaning systems, which combine precision valve configurations, smart control strategies, and efficient flushing technologies to enable uninterrupted operation with minimal manual intervention.

V.I Operating Principles of Automatic Cleaning Systems

TIANYU’s automatic cleaning system operates based on differential pressure sensing and programmed control. The system continuously monitors the pressure drop across the filter. When the differential pressure reaches a preset threshold (indicating sufficient contaminant buildup), the control system initiates the cleaning cycle.

The cleaning process involves these key steps:

-

Unit Switching: Three-way ball valves redirect flow from the dirty unit to the clean parallel unit.

-

Drain Valve Opening: Automatic drain valves open to discharge waste.

-

Backwashing Execution: Clean fluid reverses flow through the cartridge to dislodge and remove accumulated debris.

-

System Recovery: Drain valves close, and the cleaned unit returns to standby mode for the next cycle.

The entire cleaning process typically completes in seconds without interrupting the main process, significantly enhancing system uptime.

V.II Valve Configuration and Control Technology

The reliability of the automatic cleaning system heavily depends on valve configuration and control strategies. TIANYU systems incorporate the following advanced technologies:

-

Dedicated Three-Way Ball Valves: Feature low-torque design, high-strength seals, and rapid switching mechanisms for reliable and quick flow diversion.

-

High-Performance Drain Valves: Equipped with electric or pneumatic actuators for fast opening/closing and precise control.

-

Redundant Sealing Designs: Critical valves use double or triple seals to ensure leak-free operation.

-

Multiple Actuation Options: Include manual, pneumatic, electric, or hydraulic actuation to suit different automation levels.

For control systems, TIANYU uses PLCs as the core, equipped with touchscreen HMIs, offering:

-

Multiple Control Modes: Support automatic (pressure or time-triggered), semi-automatic, and manual operation.

-

Real-Time Monitoring: Continuously display system pressure, differential pressure, flow rate, and valve status.

-

Fault Diagnostics: Self-diagnostic functions identify and alarm abnormal conditions (e.g., valve failure, abnormal pressure).

-

Data Logging: Record operational parameters and historical events for troubleshooting and optimization.

-

Remote Communication: Support industrial protocols like Modbus and Profibus for integration into plant DCS or SCADA systems.

Application

V.III Application of Innovative Cleaning Technologies

TIANYU continuously introduces innovative cleaning technologies to improve efficiency and effectiveness:

-

Gas Backwashing: For viscous or stubborn contaminants, use compressed air or inert gas for pulse cleaning to enhance performance.

-

Brush Cleaning Systems: Install rotating brushes inside cartridges to mechanically assist in removing tenacious deposits.

-

Multi-Step Cleaning Cycles: Employ cycles (wetting-soaking-rinsing) for stubborn fouling to ensure thorough cleaning.

-

Water-Saving Designs: Optimize flushing sequences and nozzle designs to minimize fluid consumption and operational costs.

These technologies ensure TIANYU duplex filters excel in automatic cleaning, providing continuous, stable operation while reducing labor intensity and maintenance costs.

VI. System Selection Guide and Maintenance Practices

Selecting the appropriate duplex filter configuration and implementing effective maintenance strategies are crucial for long-term reliability. TIANYU offers comprehensive technical support and selection guidance to help users make optimal choices based on specific process conditions and needs.

VI.I Key Considerations for System Selection

When selecting a duplex filter system, consider the following technical parameters and process conditions:

-

Processing Flow Rate: Determine maximum, minimum, and normal flow rates to decide filter size and quantity.

-

Media Characteristics: Include chemical composition, viscosity, density, particle content, and size distribution.

-

Operating Conditions: Working temperature, pressure range, and fluctuations in temperature and pressure.

-

Filtration Precision: Required precision based on downstream equipment or product quality standards.

-

Material Compatibility: Select appropriate materials (304/316L stainless steel, rubber-lined carbon steel, etc.) based on media corrosiveness.

-

Automation Requirements: Decide control methods (manual/automatic) and communication interfaces based on plant automation levels.

-

Installation Environment: Consider space constraints, explosion-proof requirements, and environmental hygiene ratings.

-

Maintenance Accessibility: Consider cartridge replacement frequency, cleaning needs, and spare part availability.

TIANYU’s engineering team recommends users provide complete process data sheets for accurate sizing and system design. For special applications, trial units or pilot testing can be arranged to validate performance under actual conditions.

VI.II Installation and Commissioning Best Practices

Proper installation and commissioning are critical to achieving designed performance. Below are TIANYU’s recommended guidelines:

-

Piping Connections: Connect pipes according to flow direction arrows on the filter body to ensure correct inlet/outlet orientation.

-

Installation Orientation: Position drain ports downward to facilitate waste discharge.

-

Bypass Setup: Install bypass pipelines for easier maintenance and troubleshooting.

-

Electrical Connections: Have qualified electricians perform wiring to ensure motor rotation matches indicated direction.

-

Initial Inspection: Check internal cleanliness and tighten all fasteners before installation.

-

Pressure Testing: Conduct hydrostatic tests (typically at 0.3 MPa) to check system sealing.

-

Functional Testing: Test valve actions and control functions without load to ensure normal operation.

VI.III Preventive Maintenance and Troubleshooting

Implementing an effective preventive maintenance plan significantly extends equipment life and reduces unplanned downtime. TIANYU recommends including the following activities:

-

Daily Checks: Inspect differential pressure, leaks, and abnormal noises.

-

Scheduled Maintenance: Replace cartridges and seals based on operating hours or cycle counts.

-

Performance Monitoring: Record differential pressure trends and cleaning frequency to identify anomalies.

-

Regular Calibration: Periodically calibrate pressure sensors and control instruments.

For common issues, the table below provides diagnostic guidelines and solutions:

Table: Troubleshooting TIANYU Duplex Filters

| Symptom | Possible Causes | Solutions |

|---|---|---|

| Abnormally High ΔP | Clogged cartridge, excessive flow, high viscosity | Clean/replace cartridge, adjust flow, check temperature |

| Abnormally Low ΔP | Cartridge damage, leakage, faulty instrumentation | Check cartridge integrity, inspect seals, calibrate instruments |

| Poor Cleaning Effect | Low flushing pressure, valve failure, clogged nozzles | Increase pressure, inspect valves, clean nozzles |

| Valve Operation Issues | Actuator failure, lost control signals, sticking | Check actuator, inspect wiring, clean and lubricate |

| Media Leakage | Aged seals, loose fasteners, overpressure | Replace seals, re-tighten, check pressure |

-

Control System Abnormalities: Power failure, PLC fault, sensor failure — Check power supply, reboot system, inspect sensors.

TIANYU provides comprehensive technical training and maintenance guidance to help users establish effective maintenance systems. Additionally, TIANYU’s remote monitoring and predictive maintenance services analyze real-time system data to identify potential issues early, transitioning from reactive repairs to proactive prevention.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025