Specification

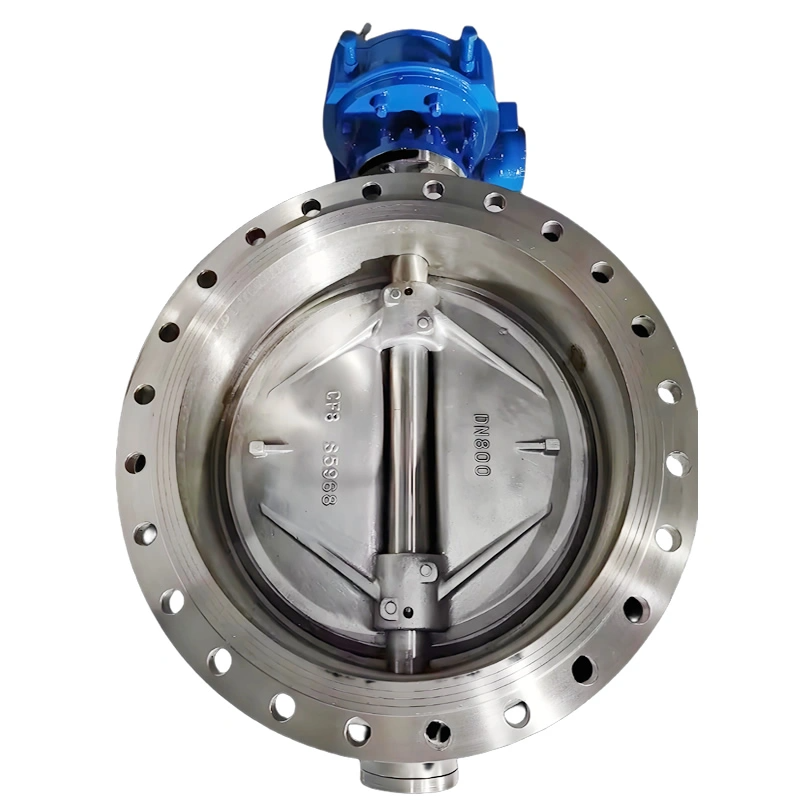

DN800 CF8 Stainless Steel Triple Eccentric Hard-Sealed Butterfly Valve

I. Product Overview

II. Key Attribute Parameters

- Size: DN800, tailored for large-diameter water pipelines requiring high flow throughput.

- Pressure Range: PN10~PN16 (1.0MPa~1.6MPa), adapting to low to medium-pressure water systems such as municipal water networks and industrial water circulation loops.

- Temperature Range: Normal temperature (-10℃~80℃), suitable for cold/hot water and non-corrosive water-based media.

- Material Configuration:

- Body & Disc: CF8 stainless steel, offering excellent corrosion resistance to water, humidity, and mild impurities—avoiding rust-related blockages.

- Sealing Pair: Hard-sealed (disc with Stellite coating, seat with alloy surfacing), ensuring tight shut-off and wear resistance under frequent operation.

- Worm Gear & Stem: Forged alloy steel and stainless steel, with anti-jamming design for smooth rotation.

- End Connections: Flanged (per GB/DIN/ANSI standards), enabling leak-tight integration with large water pipelines.

- Actuation: Worm gear drive, reducing operating torque to enable manual control of DN800 valves without excessive force.

- Design Standards: Adopts triple eccentric structure (axis, disc, seat eccentricity) to minimize friction; tested to meet industrial sealing and pressure resistance norms.

Product Overview

III. Features Description

- Triple Eccentric Structure: The valve integrates three eccentric offsets to ensure the disc only contacts the seat at full closure—avoiding friction during opening/closing. This eliminates seal wear from media scouring, a common issue in concentric valves, and ensures the seal tightens under pressure for zero leakage.

- CF8 Corrosion Resistance: CF8 stainless steel (18% Cr, 8% Ni) forms a passive oxide layer, resisting rust and pitting from water, sediment, and mild chemicals. This outperforms carbon steel in humid or long-term water immersion environments, maintaining structural integrity for decades.

- Hard-Sealed Reliability: Stellite-coated disc (hardness ≥HRC55) and alloy seat form a metal-to-metal seal, withstanding sediment-laden water without seal damage. Unlike soft seals, it avoids aging or deformation, ensuring consistent performance in outdoor or unheated pipelines.

- Worm Gear Efficiency: The worm gear drive reduces operating torque by 60% compared to direct manual operation, allowing one person to easily control DN800 valves. Its self-locking function prevents accidental rotation from pipeline vibration, critical for large water networks.

- Large Flow Capacity: The rotary disc (90° rotation) creates minimal flow resistance when fully open, with a flow coefficient (Cv) 30% higher than gate valves of the same diameter—ideal for water transmission where energy efficiency is key.

IV. Manufacturing Processes

- Material Validation: CF8 stainless steel undergoes spectral analysis to verify alloy content and ultrasonic testing to detect internal defects. Stellite powder for sealing surfaces is inspected for purity to ensure wear resistance.

- Precision Machining: Body and disc are CNC-machined to tight tolerances (±0.05mm). The disc’s sealing surface is ground to Ra ≤1.6μm, then coated with Stellite via plasma welding to 0.5~1mm thickness, followed by precision grinding.

- Eccentric Calibration: The triple eccentric parameters are calibrated using 3D measurement to ensure the disc aligns with the seat only at full closure. Worm gear meshing is adjusted to 0.1~0.2mm clearance for smooth rotation.

- Assembly & Testing:

- Components are assembled with torque-controlled fasteners, with the stem sealed via O-rings to prevent water ingress into the gearbox.

- Hydrostatic Test: Body tested at 1.5×PN (2.4MPa for PN16) for 30 minutes; seat tested at 1.1×PN with water to confirm no leakage.

- Operation Test: 50+ open/close cycles to verify worm gear smoothness and disc positioning accuracy.

Valve Details

V. Product Advantages

- Zero Leakage in Water Systems: Triple eccentric and hard-sealed design eliminate leakage, reducing water loss by 99% compared to standard valves—critical for municipal water networks where efficiency is regulated.

- Long Service Life: CF8 corrosion resistance and Stellite wear resistance extend service life to 15~20 years, reducing replacement costs in large-diameter pipeline projects.

- Energy & Cost Savings: Low flow resistance cuts pump energy consumption by 10~15% in water transmission. Worm gear operation avoids the need for expensive actuators in manual systems.

- Maintenance Convenience: Flanged connection allows in-line inspection; worm gear components are modular for easy replacement, minimizing downtime in critical water supply.

- Environmental Adaptability: Resists rust, UV damage, and temperature fluctuations, adapting to outdoor, underground, or industrial water pipelines without performance degradation.

Application

VI. Application Fields

- Municipal Water Supply: Controls flow in large-diameter water mains, with corrosion resistance adapting to long-term underground installation and tight sealing preventing water loss.

- Wastewater Treatment: Regulates flow in secondary treatment and discharge lines, with hard seals resisting abrasion from sludge and CF8 material withstanding mild chemical cleaners.

- Industrial Circulation: Manages cooling water flow in power plants or factories, leveraging large flow capacity to meet high-demand systems and avoid pressure drops.

- Irrigation Projects: Controls water distribution in agricultural canals, with weather-resistant design adapting to outdoor conditions and reliable sealing preventing water waste.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025