Specification

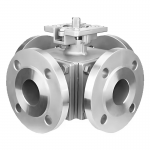

TIANYU DN80 PN16 Stainless Steel 304/316 Manual Multi-Port 4-Way Flange Ball Valve

I. Product Overview

TIANYU DN80 PN16 stainless steel 304/316 manual multi-port 4-way flange ball valve is a versatile flow control solution engineered to manage complex fluid distribution in industrial systems. Designed with four ports and a manually operated ball, it combines the corrosion resistance of stainless steel with the flexibility of multi-directional flow management, making it ideal for applications requiring media diversion, mixing, or isolation. Operating at a pressure rating of PN16 (1.6MPa) and compatible with temperatures ranging from -20℃ to 150℃, this valve excels in handling water, oils, chemicals, and gases—serving sectors such as chemical processing, water treatment, food and beverage, and industrial fluid systems. Its flange connection ensures secure integration into pipelines, while the manual operation provides reliable, hands-on control in scenarios where automation is unnecessary or impractical.

II. Key Attribute Specifications

| Category | Details |

|---|---|

| Size | DN80 (3”), suitable for medium-flow pipelines requiring multi-directional flow control. |

| Pressure Rating | PN16 (1.6MPa), designed for low-to-medium pressure systems in industrial and commercial applications. |

| Temperature Range | -20℃~150℃ (with PTFE seats); up to 200℃ with metal seats, accommodating diverse media temperatures. |

| Material Composition | – Valve Body & Ball: Stainless steel 304 (18Cr-8Ni) as standard, offering excellent corrosion resistance to water, mild acids, and neutral fluids; 316 (16Cr-10Ni-2Mo) optional for enhanced resistance to chlorides, alkalis, and aggressive chemicals. – Seat: PTFE (polytetrafluoroethylene) for general service, providing chemical inertness and low-friction sealing; metal seats (stellite-coated) optional for high-temperature or abrasive media. – Stem & Handle: Stainless steel 304/316 stem with a cast iron or stainless steel manual handle, ensuring durability and corrosion resistance. |

| Connection Type | Flange (ASME B16.5, RF), compatible with standard pipeline flanges and gaskets (e.g., spiral-wound, non-asbestos) for leak-tight installation. |

| Port Configuration | 4-way design with ports labeled as A, B, C, D (typically arranged in a cross or L-shape), supporting flow combinations such as A→B & C→D, A→C & B→D, or full isolation of individual ports. |

| Operation | Manual lever handle with 90° rotation, featuring a position indicator (open/closed) and lockable design to prevent unauthorized operation. |

| Performance Metrics | – Leakage Class: ANSI/FCI Class V (bubble-tight for liquids), ensuring ≤0.1×DN mm³/min leakage under test pressure. – Cycle Life: ≥50,000 operations with consistent sealing performance. – Flow Coefficient (Cv): 120~150 (varies by port configuration), indicating high flow capacity with minimal pressure drop. |

Product Overview

III. Feature Description

A. 4-Way Port Design for Versatile Flow Management

The valve’s defining feature is its four-port configuration, which enables multiple flow patterns to suit complex system needs. Unlike 2-way or 3-way valves, it can simultaneously control two independent flow paths (e.g., directing media from A→B while isolating C→D) or redirect flow between all four ports. This versatility eliminates the need for multiple valves in systems requiring frequent reconfiguration—for example, in a chemical mixing plant, it can switch between “tank A to reactor” and “tank B to drain” without disrupting other processes. The cross-shaped internal flow channels are precision-machined to minimize turbulence, ensuring uniform flow distribution and reducing pressure drop across the valve.

B. Stainless Steel 304/316 Corrosion Resistance

Constructed from stainless steel 304 or 316, the valve withstands corrosion from a wide range of media, including water, salts, mild acids, and industrial chemicals. Stainless steel 304 is ideal for general applications like water treatment or food processing, where resistance to rust and hygiene are critical. For harsher environments—such as coastal facilities, chloride-rich water systems, or chemical plants handling alkalis—316 stainless steel (with molybdenum) provides enhanced pitting and crevice corrosion resistance, extending service life in aggressive conditions. The smooth, polished internal surfaces (Ra ≤0.8μm) prevent media buildup, reducing the risk of clogging in systems with particulate-laden fluids.

C. Manual Operation with Precise Control

The manual lever handle allows for direct, intuitive operation, with 90° rotation to switch between flow configurations. This simplicity makes it suitable for systems where flow changes are infrequent or where manual oversight is preferred—such as in small-scale industrial plants or backup lines. The handle is equipped with a position indicator (e.g., “A→B/C→D”) to clearly show the current flow path, reducing operator error. A lockable feature (via padlock) prevents accidental or unauthorized adjustments, critical in safety-critical applications like chemical dosing lines.

D. Bubble-Tight Sealing with PTFE/Metal Seats

The valve uses PTFE seats as standard, a material renowned for chemical inertness, low friction, and flexibility. PTFE conforms to the ball’s surface to create a tight seal, ensuring zero leakage for liquids and gases even under fluctuating pressures. For high-temperature applications (up to 200℃) or abrasive media (e.g., slurries with fine particles), optional metal seats (stellite-coated) provide wear resistance and thermal stability, avoiding degradation that could compromise sealing. The seats are mechanically retained to prevent displacement under high flow velocities, a key feature in high-pressure systems.

E. Flange Connection for Secure Integration

Flange connections (ASME B16.5) ensure the valve integrates seamlessly into existing pipelines, with bolted joints distributing pressure evenly across the sealing surface. This design simplifies installation and maintenance—technicians can remove or replace the valve without cutting into the pipeline, reducing downtime in critical systems. The raised face (RF) flange profile enhances gasket contact, minimizing leakage risk in applications with pressure fluctuations, such as water distribution networks or industrial process lines.

IV. Manufacturing Processes

A. Material Preparation & Quality Validation

- Stainless Steel Sourcing: 304/316 stainless steel billets are sourced from certified suppliers, with chemical composition verified via spectral analysis to ensure compliance with ASTM standards (e.g., 304: 18-20% Cr, 8-10.5% Ni; 316: 16-18% Cr, 10-14% Ni, 2-3% Mo).

- Defect Detection: Billets undergo ultrasonic testing to identify internal flaws (porosity, cracks) that could compromise pressure integrity, ensuring structural reliability in high-pressure applications.

B. Precision Machining of Valve Components

- Body & Ports: The valve body is CNC-machined to create four ports and internal flow channels, with strict tolerances (±0.05mm) to ensure uniform flow distribution. Flange faces are machined to Ra ≤3.2μm, ensuring compatibility with pipeline gaskets.

- 4-Way Ball Fabrication: The ball is CNC-machined from a solid stainless steel block, with cross-shaped or L-shaped flow paths ground to a smooth finish (Ra ≤0.8μm). This precision ensures the ball aligns perfectly with the seats in all positions, critical for bubble-tight sealing.

- Stem & Handle: The stem is precision-ground to fit the body’s packing chamber, with a keyway to connect securely to the ball. The manual handle is cast and machined to fit the stem, with a ergonomic grip for easy operation.

C. Sealing System Assembly

- Seat Installation: PTFE or metal seats are compression-molded to match the ball’s contours, then press-fitted into the body’s seat pockets. Retaining rings secure the seats in place, preventing displacement under flow pressure.

- Packing Assembly: Graphite-impregnated PTFE packing is wrapped around the stem to form a gas-tight seal, compressed by a packing gland to balance leak resistance and smooth handle operation.

D. Final Assembly & Testing

- Ball & Stem Integration: The 4-way ball is keyed to the stem, which is then inserted into the body and secured with a yoke. The handle is attached to the stem, with a position indicator calibrated to match flow configurations.

- Hydrostatic Testing: The valve body is pressurized to 1.5×PN16 (2.4MPa) with water for 30 minutes, with no visible leakage or deformation, verifying structural integrity.

- Seat Leak Testing: Under 1.1×PN16 (1.76MPa) pressure (water for liquids, nitrogen for gases), leakage is measured to ensure compliance with ANSI/FCI Class V.

- Operation Testing: The handle is rotated through 90° cycles to confirm smooth operation, with each flow configuration verified for proper port alignment and sealing.

Valve Details

V. Product Advantages

A. Reduced System Complexity

The 4-way design replaces multiple 2-way or 3-way valves, simplifying pipeline layouts and reducing potential leak points. In a water treatment plant, for example, one valve can control flow between four tanks, eliminating the need for six 2-way valves and lowering installation costs by 40%.

B. Versatile Flow Configurations

With the ability to switch between multiple flow paths, the valve adapts to changing process needs without system reconfiguration. This flexibility is invaluable in batch processing (e.g., food manufacturing), where production lines frequently switch between ingredients or cleaning cycles.

C. Corrosion Resistance for Longevity

Stainless steel 304/316 and PTFE seats resist degradation from corrosive media, extending service life to 10+ years in typical applications. In coastal water systems, 316 valves require 50% fewer replacements than carbon steel alternatives, reducing maintenance costs.

D. Reliable Manual Control

Manual operation eliminates the need for power sources or complex actuators, making the valve suitable for remote locations or backup systems. The lockable handle enhances safety by preventing unauthorized adjustments, critical in chemical or food processing where flow errors could cause product contamination.

E. High Flow Efficiency

Precision-machined ports and internal channels minimize pressure drop, ensuring efficient fluid transfer. In industrial fluid systems, this reduces pump energy consumption by up to 15% compared to restrictive valve designs, lowering operational costs.

Application

VI. Product Applications

A. Chemical Processing

- Batch Reactor Systems: Directs raw materials from multiple storage tanks to reactors, with 4-way configuration enabling quick switching between ingredients without disrupting processes.

- Waste Treatment Lines: Manages flow between chemical neutralization tanks, isolation of contaminated fluids, and diversion to drain lines, simplifying waste handling.

B. Water Treatment & Distribution

- Municipal Water Networks: Controls flow between source water, treatment tanks, distribution lines, and bypass systems, allowing for maintenance of individual components without service interruptions.

- Industrial Water Recycling: Directs water between filtration units, storage tanks, and process lines, with 4-way functionality enabling easy 切换 between fresh and recycled water.

C. Food & Beverage Production

- Ingredient Mixing: Manages flow of multiple ingredients (e.g., syrups, additives) to mixing tanks, with sanitary 304 stainless steel construction meeting FDA standards.

- Clean-in-Place (CIP) Systems: Switches between product flow and cleaning fluid circulation, ensuring thorough equipment sanitization without disassembly.

D. Industrial Fluid Systems

- Hydraulic & Lubrication Lines: Controls flow between pumps, reservoirs, and machinery, with 4-way design enabling pressure relief and fluid diversion during maintenance.

- Cooling Water Circuits: Directs coolant between chillers, heat exchangers, and process equipment, allowing for temperature regulation and system balancing.

TIANYU DN80 PN16 4-way manual ball valve: 3” size, 1.6MPa, 304/316 stainless steel, flange connection. Offers versatile flow control, corrosion resistance, and reliable manual operation for industrial systems.Customize with: 316L for extreme corrosion, metal seats for high temps, extended handles for tight spaces, or sanitary polish for food applications. Tailored to your media, pressure, and flow needs.