Specification

| No. | Part name | Material | |||

| 1 | Body | GGG40 | |||

| 2 | Disc/shaft one piece | CF8M | 1.4462 | CF8M FEP lined | CF8 EPDM lined |

| 3 | Seat | PTFE,FPM,EPDM,PU,NBR | PTFE | EPDM | |

| 4 | Seat Energizer | SR | |||

| 5 | Weather seal | NBR | |||

| 6 | Bearing | PTFE impregnated SS316L | |||

| 7 | Gland | PTFE | |||

| 8 | Screw | SS304 | |||

| 9 | Belleville washer | SS304 | |||

| 10 | Stuffing collar | SS316 | |||

| 11 | O ring | FPM | |||

| 12 | V ring | PTFE | |||

TECHNICAL DATA

| Body style | wafer |

| Nominal diameter | 2″ – 24″ (DN50mm – DN600mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN200, 10bar for DN250-DN600 |

| Temperature range | -20 °C to + 180 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

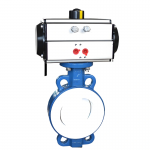

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

Pneumatic actuator

| action | |

| Double acting Failure to maintain | Maintains position on air failure |

| Single acting normally closed Failure to close | Fails to open |

| Single acting normally open Failure to open | Fails to close |

| Optional accessory | Solenoid valve limit switch box air filter relief pressure valve, E/P positioned manual device. |

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | |

| DN | INCH | |||||||||||

| 50 | 2″ | 126 | 65 | 13.5 | 116 | 11 | 50 | 8 | 65 | 25 | 43 | 2 |

| 65 | 2 1/2″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 80 | 3″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 100 | 4″ | 167 | 97 | 17.5 | 170 | 14 | 70 | 10 | 90 | 86 | 52 | 5 |

| 125 | 5″ | 180 | 129 | 17.5 | 196 | 14 | 70 | 10 | 90 | 112 | 56 | 7 |

| 150 | 6″ | 203 | 142 | 18.5 | 227 | 17 | 70 | 10 | 90 | 140 | 56 | 8 |

| 200 | 8″ | 228 | 172 | 18.5 | 279 | 17 | 102 | 12 | 125 | 191 | 60 | 13 |

| 250 | 10″ | 266 | 213 | 24.5 | 336 | 22 | 102 | 12 | 125 | 241 | 58 | 22 |

| 300 | 12″ | 291 | 242 | 24.5 | 392 | 22 | 102 | 12 | 125 | 290 | 78 | 31 |

| 350 | 14″ | 332 | 262 | 30 | 445 | 27 | 125 | 14 | 150 | 331 | 78 | 44 |

| 400 | 16″ | 363 | 303.5 | 30 | 503 | 27 | 125 | 14 | 150 | 377 | 102 | 64 |

| 450 | 18″ | 397 | 324.5 | 39 | 553 | 36 | 140 | 18 | 175 | 425 | 114 | 86 |

| 500 | 20″ | 425 | 357 | 39 | 608 | 36 | 140 | 18 | 175 | 474 | 127 | 116 |

| 600 | 24″ | 498 | 419 | 49 | 717 | 46 | 165 | 22 | 210 | 570 | 154 | 179 |

Product Overview

I. Product Overview

II. Key Attribute Parameters

- Size Range: DN50 ~ DN600 (2″ ~ 24″), covering medium to large-diameter pipelines for diverse flow control needs.

- Pressure Range: 16bar (DN50 ~ DN200); 10bar (DN250 ~ DN600), adapting to low to medium pressure corrosive media systems.

- Temperature Range: -20℃ ~ 180℃, compatible with PTFE and rubber seals for media with moderate temperature fluctuations.

- Material Configuration:

- Body: GGG40 ductile iron (high strength, shock resistance) with PTFE lining (corrosion barrier for aggressive media).

- Disc & Shaft: One-piece structure, material options include CF8M (1.4462), CF8M FEP lined, CF8 EPDM lined—balancing strength and corrosion resistance.

- Seat: PTFE, FPM, EPDM, PU, NBR; PTFE for strong chemicals, rubber for general industrial media.

- Bearings: PTFE-impregnated SS316L (self-lubricating, corrosion-resistant).

- Actuator: Pneumatic (double acting/single acting), with single acting offering fail-safe (normally open/closed) functionality.

- Connection Type: Wafer-style, fitting between pipeline flanges to save installation space.

- Flange Compatibility: EN 1092 PN6/PN10/PN16, ASME Class 150, JIS 5K/10K, ensuring global pipeline integration.

III. Features Description

- PTFE Lining Corrosion Resistance: The valve body and internal flow path are lined with PTFE—a material inert to most acids, alkalis, and solvents. This lining isolates corrosive media from the GGG40 body, eliminating metal corrosion and extending service life in chemical dosing or acid transfer systems.

- Three-Layer Sealing System: Combines PTFE seat, siliccone, and V-ring packing to achieve bubble-tight shut-off (ANSI/FCI Class VI). The siliccone ensures stable sealing under pressure fluctuations, while the V-ring prevents external leakage at the shaft.

- One-Piece Disc-Shaft Design: Integral construction reduces torque requirements by 20% compared to split designs, enhancing operational efficiency. It also eliminates leakage risks at the disc-shaft connection—critical for toxic or hazardous media.

- Self-Lubricating Bearings: PTFE-impregnated SS316L bearings ensure precise disc-shaft alignment, reducing friction and wear during rotation. This design maintains smooth operation even in dusty or humid environments.

- Pneumatic Actuation Flexibility: Double acting for continuous process control; single acting (spring-return) for safety—automatically returning to default position if air supply fails, preventing media overflow in unattended systems.

Valve Details

IV. Manufacturing Processes

- Material Preparation: GGG40 castings undergo ultrasonic testing to detect internal defects. PTFE sheets are inspected for uniformity (no bubbles or impurities) to ensure corrosion resistance.

- PTFE Lining Formation: The valve body interior is sandblasted to roughen the surface, then PTFE is molded and sintered (380℃ ~ 400℃) to bond tightly with the metal—preventing lining detachment under thermal expansion.

- Disc-Shaft Machining: One-piece CF8M disc-shaft is precision-machined to ensure concentricity (±0.05mm), avoiding jamming during rotation. Lined disc options (FEP/EPDM) are coated via electrostatic spraying for uniform thickness (0.3mm ~ 0.5mm).

- Seal Assembly: PTFE seats are lapped with the disc to achieve Ra ≤0.8μm surface contact, ensuring tight sealing. Silicon rubber energizers are installed behind seats to maintain pressure on sealing surfaces during temperature changes.

- Testing:

- Pressure Test: Body tested at 1.5×rated pressure (water) for 30 minutes; seat tested at 1.1×rated pressure (air) to verify no leakage.

- Corrosion Test: PTFE-lined components immersed in 50% sulfuric acid for 72 hours—no lining damage or metal corrosion allowed.

- Actuator Cycle Test: 10,000+ open/close cycles under 6bar air supply to confirm smooth operation.

V. Product Advantages

- Superior Corrosion Resistance: PTFE lining and SS316L components resist acids, alkalis, and solvents, reducing replacement costs by 40% compared to unlined metal valves in chemical applications.

- Low Operational Torque: One-piece disc-shaft and self-lubricating bearings lower actuation energy requirements, ideal for energy-saving automated systems.

- Bubble-Tight Sealing: Three-layer sealing and precision lapping achieve Class VI leakage, preventing hazardous media escape in pharmaceutical or toxic chemical processes.

- Easy Maintenance: Wafer design simplifies installation/removal; components are disassemblable for material-specific recycling or replacement—minimizing downtime.

- Safety Compliance: Single acting actuator’s fail-safe function and leak-proof design meet industrial safety standards for corrosive media handling.

Application

VI. Application Fields

- Chemical Industry: Controls acids (sulfuric acid, nitric acid), alkalis (sodium hydroxide), and solvents in dosing, reaction, and transfer systems—PTFE lining resists chemical attack.

- Oil Refining: Regulates corrosive by-products (e.g., amine solutions) in desulfurization processes, with PTFE avoiding degradation from sulfur compounds.

- Water Treatment: Manages corrosive wastewater (e.g., heavy metal-containing effluent) and chemical disinfectants (chlorine, ozone)—preventing valve corrosion.

- Pharmaceuticals: Handles high-purity solvents and cleaning agents, with PTFE ensuring no media contamination (meets FDA standards for indirect food contact).

- Electroplating: Controls plating solutions (acids, metal salts) in coating lines, where corrosion resistance is critical for consistent process quality.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025