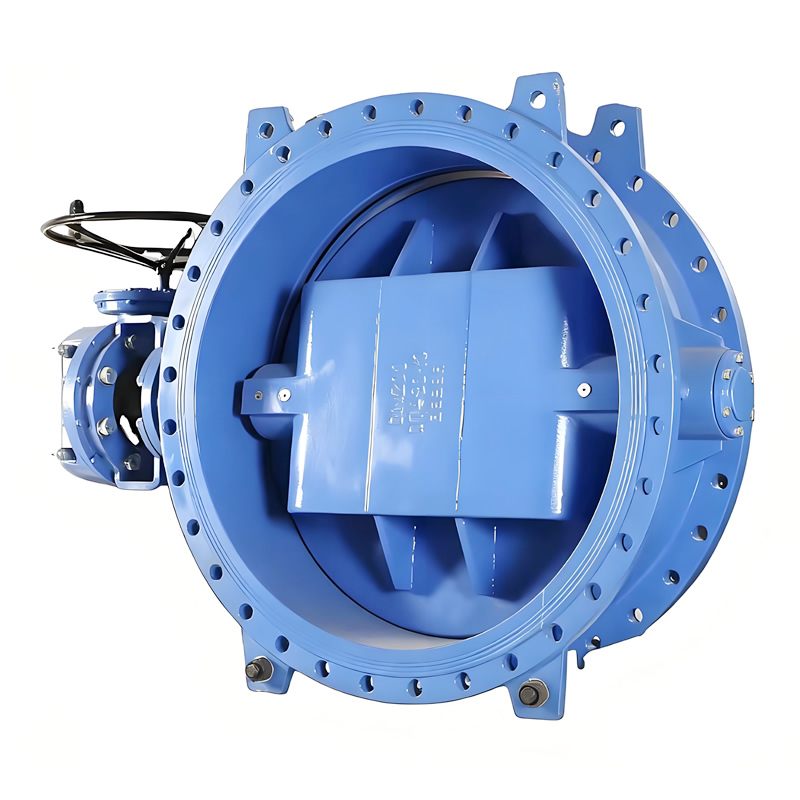

TIANYU DN50-DN3000 Manual Double Eccentric Butterfly Valve: PTFE Soft Seal & Metal Hard Seal Flow Control Solution for Water Media in Industrial & Municipal Pipelines

I. Product Overview

II. Key Attribute Specifications

A. Dimensional & Pressure-Temperature Parameters

- Nominal Diameter (Port Size): DN50 to DN3000 (2 inches to 120 inches), covering the full spectrum of small to extra-large diameter pipelines. The full-port design minimizes pressure drop, with a flow coefficient (Cv) ranging from 50 (DN50) to 18,000 (DN3000), ensuring efficient water transfer without compromising system performance. For example, a DN3000 valve can handle up to 12,000 m³/h of water at 20℃, meeting the flow demands of large municipal water treatment plants or industrial cooling circuits.

- Pressure Rating: Low-pressure (PN0.6MPa, PN1.0MPa, PN1.6MPa) and high-pressure (PN2.5MPa, PN4.0MPa, PN6.4MPa) options, accommodating diverse system pressures from residential water lines (PN0.6MPa) to industrial high-pressure cooling systems (PN6.4MPa). Hydrostatic test pressure adheres to API 598 standards: 1.5×rated pressure for the valve shell (e.g., 9.6MPa for PN6.4) and 1.1×rated pressure for the seat (e.g., 7.04MPa for PN6.4), ensuring structural integrity and leak-tight performance.

- Temperature Range: Dependent on sealing type:

- PTFE Soft Seal: -20℃ to 200℃, suitable for ambient and moderately heated water media (e.g., domestic hot water, industrial process water).

- Metal Hard Seal (Stellite 6): -20℃ to 400℃, designed for high-temperature water systems (e.g., power plant feedwater, industrial steam condensate).

B. Material Composition

- Valve Body:

- Ductile Iron (QT450-10): Cost-effective option for low-pressure municipal applications (PN≤1.6MPa) such as residential water supply. Offers tensile strength of 450MPa, impact resistance, and corrosion resistance via epoxy coating for buried or outdoor installations.

- Cast Steel (WCB, ASTM A216): Suitable for medium-to-high-pressure industrial use (PN≤6.4MPa) and high-temperature water systems. Tensile strength of 485–655MPa and yield strength ≥240MPa ensure resistance to thermal stress and pressure fluctuations.

- Stainless Steel (304/316, ASTM A182): Recommended for corrosive water media (e.g., seawater, chlorinated wastewater) or hygienic applications (e.g., pharmaceutical process water). 304 stainless steel (18Cr-8Ni) resists mild corrosion, while 316 stainless steel (16Cr-10Ni-2Mo) enhances resistance to chlorides and sulfides—ideal for coastal or chemical processing environments.

- Butterfly Disc:

- Stainless Steel (304/316): Matches valve body material for corrosion resistance, with a streamlined profile to minimize pressure drop. Precision-machined to ensure concentricity with the valve body.

- Alloy Steel (1045): For high-pressure applications (PN≥4.0MPa), heat-treated to hardness 28–32 HRC for wear resistance.

- Ductile Iron with Epoxy Coating: Cost-effective alternative for low-pressure, non-corrosive water media, with epoxy coating preventing rust and scaling.

- Valve Stem:

- Stainless Steel (2Cr13/304): Corrosion-resistant and high-strength, with precision grinding to ensure smooth rotation. Equipped with anti-blowout design to prevent stem ejection under pressure.

- Sealing System:

- PTFE Soft Seal: Polytetrafluoroethylene (PTFE) seat with reinforced carbon fiber for enhanced mechanical strength. Chemical inert to water and most mild chemicals, delivering ANSI/FCI Class VI leakage performance (≤0.1×DN mm³/min) for bubble-tight sealing. Operating temperature: -20℃ to 200℃.

- Metal Hard Seal: Stellite 6 (cobalt-based alloy) surfacing on disc and seat, hardness ≥58 HRC. Resists high temperatures, abrasion, and minor particle contamination in water media. Leakage performance: ANSI/FCI Class IV (≤0.01% of rated flow). Operating temperature: -20℃ to 400℃.

C. Connection & Operational Features

- Connection Type: Flanged (Raised Face, RF) as standard, complying with ASME B16.5 (USA), GB/T 9115.1 (China), and EN 1092-1 (Europe). Wafer and lug connections are optional for small-to-medium diameters (DN50–DN600) in low-pressure systems. The RF flange design ensures secure gasket sealing, compatible with spiral-wound gaskets (stainless steel + graphite) for high-temperature/pressure service or non-asbestos gaskets for general use.

- Operation Mode: Manual, with two options:

- Lever Operation: For small diameters (DN50–DN200), 90° rotation for quick on-off control. Lever length is optimized to reduce operating torque (≤150N·m for DN200 PN1.6).

- Handwheel Operation: For medium-to-large diameters (DN250–DN3000), gear reduction handwheel reduces torque by 60–70% (≤800N·m for DN3000 PN1.6), enabling single-person operation. Ergonomic handwheel design with anti-slip grip for comfort in extended use.

- Structural Features: Double eccentric design—eccentricity between valve shaft and disc center, and between disc center and seal face. This structure eliminates contact between disc and seat during 80% of the opening/closing stroke, reducing friction and wear. Bidirectional sealing capability, suitable for bi-flow pipeline systems (e.g., bypass loops, water distribution networks).

- Safety Features: Valve stem position indicator (open/closed) for visual confirmation; anti-static device (optional) to discharge static electricity in dry water systems or industrial environments; lockable lever/handwheel (optional) to prevent unauthorized operation.

D. Certifications & Compliance

- Core Certifications: ISO 9001 (quality management system), CE (EU safety compliance), GB/T 19001 (Chinese quality standard).

- Industry-Specific Certifications: API 609 (industrial butterfly valves), ensuring compliance with design, testing, and performance requirements for oil, gas, and water applications. Optional NACE MR0175/ISO 15156 certification for sour service (corrosive water media with H₂S).

- Dimensional & Testing Compliance: ASME B16.34 (valve pressure-temperature ratings), GB/T 12238 (double eccentric butterfly valve design), API 598 (valve testing and inspection), ensuring compatibility with global pipeline components and reliable performance.

III. Feature Description

A. Double Eccentric Structure: Low Wear & Extended Service Life

- Friction Reduction: Unlike concentric valves (where disc and seat rub throughout the stroke), the double eccentric design lifts the disc away from the seat during opening, minimizing contact to only the final 5–10° of closure. This reduces seal wear by 70% compared to concentric models, extending service life from 3–5 years to 8–12 years in typical water applications.

- Uniform Sealing Pressure: The second eccentricity ensures the disc presses evenly against the seat, creating a tight seal across the entire contact surface. This eliminates leakage points caused by uneven pressure, critical for water media where even minor leakage wastes resources or disrupts processes.

- Bidirectional Sealing: The design enables reliable sealing in both flow directions, eliminating the need for check valves in bi-flow systems (e.g., municipal water mains with reverse flow during maintenance).

B. Dual Sealing Options: Adaptability to Diverse Conditions

- PTFE Soft Seal: Ideal for low-to-medium temperature water systems (≤200℃) such as municipal drinking water, HVAC chilled water, and industrial process water. PTFE’s chemical inertness resists corrosion from chlorinated water or mild impurities, while its elasticity delivers ANSI Class VI bubble-tight sealing—critical for potable water networks to prevent contamination.

- Metal Hard Seal (Stellite 6): Engineered for high-temperature (≤400℃) and high-pressure (≥PN4.0MPa) water systems, such as power plant boiler feedwater, industrial steam condensate, or water with fine abrasive particles (e.g., river water intake). Stellite 6’s extreme hardness (≥58 HRC) resists wear and deformation, maintaining ANSI Class IV leakage performance even after 10,000+ cycles.

C. Manual Operation: Cost-Effective & Easy to Maintain

- Locations without power access (e.g., remote water pumping stations, rural irrigation systems).

- Low-frequency operation scenarios (e.g., pipeline maintenance isolation, seasonal flow adjustment).

- Budget-sensitive projects (e.g., small municipal wastewater plants, residential building water lines).

The ergonomic design ensures ease of use: lever operation for small valves takes only 1–2 seconds per cycle, while gear-reduction handwheels allow single-person control of DN3000 valves with minimal effort.

D. Wide Diameter Range: Scalability Across Applications

- Small Diameters (DN50–DN200): Used in residential building water supply, HVAC terminal units, and small industrial process lines. Lever operation and compact design save space and installation costs.

- Medium Diameters (DN250–DN1000): Deployed in municipal water distribution networks, industrial cooling water circuits, and wastewater treatment plant process lines. Gear-reduction handwheels balance torque and operation efficiency.

- Large Diameters (DN1200–DN3000): Installed in large-scale water mains, reservoir intake/outlet lines, and industrial cooling towers. Robust construction with reinforced valve bodies and shafts withstands high flow velocities and pressure fluctuations.

E. Durable Material Selection: Corrosion Resistance & Longevity

- Stainless Steel (304/316): Resists rust and pitting from chlorinated water, seawater, and industrial wastewater, making it suitable for coastal municipalities and chemical plants.

- Cast Steel (WCB): Offers high tensile strength and thermal stability for high-pressure/high-temperature water systems, such as power plant auxiliary lines.

- Ductile Iron (QT450-10): Cost-effective and impact-resistant for low-pressure municipal applications, with epoxy coating enhancing corrosion resistance in buried pipelines.

- Stellite 6: Ensures metal seal durability in abrasive or high-temperature water, outperforming carbon steel seals by 3–4 times in service life.

IV. Manufacturing Processes

A. Material Inspection & Preparation

- Raw Material Verification: All metallic materials undergo rigorous testing to ensure compliance with standards:

- Stainless steel (304/316) and cast steel (WCB) billets are tested via spectral analysis to confirm chemical composition (e.g., Cr: 18–20% for 304, C: 0.25–0.35% for WCB). Ultrasonic testing (UT) and magnetic particle inspection (MPI) detect internal defects (porosity, cracks) in cast components.

- Ductile iron (QT450-10) is tested for tensile strength and impact resistance, ensuring compliance with ASTM A536.

- PTFE seal materials are inspected for compression set (≤20% after 70 hours at 200℃) and chemical purity, meeting FDA 21 CFR 177.1550 standards for food-grade water applications.

- Surface Preparation:

- Cast components are sandblasted to remove scale and surface defects, improving paint adhesion (for ductile iron) or passivation (for stainless steel).

- Stainless steel components undergo acid passivation to enhance the chromium oxide passive layer, boosting corrosion resistance.

- Valve stems are precision-ground to a surface roughness of Ra ≤0.4μm to reduce friction with packing.

B. Precision Machining of Double Eccentric Structure

- Valve Body Machining: CNC turning and milling centers shape the valve body, with flange faces machined to flatness tolerance ≤0.05mm/m and surface finish Ra ≤3.2μm for proper gasket seating. Internal seat pockets are honed to a diameter tolerance of H7 (0–+0.03mm) to ensure precise fit with seals.

- Disc Machining: The double eccentric disc is CNC-machined to spherical tolerance ±0.02mm, with seal faces lapped to Ra ≤0.8μm. For metal-sealed valves, Stellite 6 is welded to the disc and seat via TIG welding, then ground to a uniform thickness of 1.5–2.0mm.

- Shaft Machining: Valve shafts are turned, ground, and polished to diameter tolerance h7 (±0.015mm), with keyways machined to fit levers/handwheels securely. Anti-blowout shoulders are integrated into the shaft design to prevent ejection under pressure.

C. Seal Installation & Assembly

- Soft Seal Installation: PTFE seats are precision-cut to match the disc’s curvature, then press-fitted into the valve body with retaining rings. Spring-loading (optional) compensates for thermal expansion and wear, maintaining sealing pressure over time.

- Hard Seal Installation: Stellite 6-sealed seats are welded to the valve body, then lapped with the disc to ensure uniform contact. The disc is adjusted to ensure 0.1–0.2mm preload against the seat for tight sealing.

- Final Assembly: The disc-shaft assembly is inserted into the valve body, with bronze or PTFE packing installed around the shaft to prevent water leakage. Levers or gear-reduction handwheels are mounted, and torque is calibrated to ensure smooth 90° rotation.

D. Quality Testing & Certification

- Hydrostatic Testing:

- Shell Test: The valve body is filled with water and pressurized to 1.5×rated pressure for 30 minutes. No leakage, sweating, or deformation is allowed—test results are documented in a hydrostatic test report.

- Seat Test: The valve is closed, and water is pressurized to 1.1×rated pressure on one side. Leakage is measured via a flow meter: ≤0.1×DN mm³/min for PTFE seals (ANSI Class VI) and ≤0.01% of rated flow for metal seals (ANSI Class IV).

- Operational Testing:

- The valve undergoes 100 open-close cycles to verify smooth operation. Torque is recorded at each cycle (variation ≤5%) to ensure consistency.

- Lever/handwheel operation is tested to confirm single-person operation for all diameters, with torque values documented for reference.

- Dimensional Inspection: Flange dimensions, face-to-face length, and eccentricities are verified using coordinate measuring machines (CMM) to comply with ASME B16.5 and GB/T 12238.

- Certification Documentation: Each valve is accompanied by a Material Test Report (MTR), hydrostatic test report, and compliance certificates (ISO 9001, CE, API 609 if applicable).

V. Product Advantages

A. Low Wear & Extended Service Life

B. Dual Sealing for Versatile Operation

C. Cost-Effective Manual Operation

D. Wide Application Range & Scalability

E. Corrosion Resistance & Durability

F. Global Standard Compliance & Compatibility

VI. Product Applications

A. Municipal Water Supply & Drainage

- Water Distribution Networks: DN200–DN3000 valves control flow in municipal water mains, with PTFE soft seals ensuring potable water quality (ANSI Class VI leakage). The double eccentric design’s bidirectional sealing adapts to reverse flow during maintenance, and gear-reduction handwheels enable easy operation of large-diameter valves.

- Wastewater Treatment Plants: DN100–DN1000 valves regulate flow in sewage collection, aeration tanks, and effluent discharge lines. 316 stainless steel bodies and PTFE seals resist corrosion from chlorine-based disinfectants, while metal-sealed valves handle high-temperature sludge digestion systems (≤300℃).

B. Industrial Cooling Water Systems

- Thermal Power Plants: DN500–DN2000 metal-sealed valves control boiler feedwater and cooling water flow (PN4.0MPa, 350℃). Stellite 6 seals withstand high temperatures and abrasive particles, ensuring reliable operation in continuous-process environments.

- Manufacturing Facilities: DN50–DN600 valves regulate cooling water for machinery, molds, and production lines. PTFE soft seals prevent water leakage, and manual operation simplifies maintenance in factory settings.

C. Chemical & Pharmaceutical Industry

- Chemical Processing: DN50–DN400 316 stainless steel valves handle corrosive water-based solutions (e.g., chlorinated solvents, dilute acids). PTFE’s chemical inertness prevents media contamination, while the double eccentric design’s low wear ensures long service life in batch processes.

- Pharmaceutical Manufacturing: DN50–DN200 electropolished 316L stainless steel valves with PTFE seals meet GMP (Good Manufacturing Practice) requirements for high-purity water systems. The smooth internal surfaces (Ra ≤0.4μm) prevent bacterial growth, ensuring product safety.

D. Building HVAC & Plumbing

- Commercial Buildings: DN50–DN200 lever-operated valves control chilled water and hot water flow in HVAC systems. Compact design saves space in mechanical rooms, and PTFE seals maintain efficiency by preventing leakage.

- Residential Complexes: DN50–DN100 ductile iron valves regulate water supply to individual buildings or units. Cost-effective manual operation and epoxy coating (for buried installation) reduce maintenance and replacement costs.

E. Water Treatment & Irrigation

- Water Treatment Plants: DN300–DN1500 valves control raw water intake, filtration, and disinfection processes. PTFE soft seals ensure zero leakage in potable water lines, while metal-sealed valves handle backwash systems with high-pressure water (PN2.5MPa).

- Irrigation Systems: DN50–DN300 valves regulate water flow in agricultural irrigation networks. Manual operation is ideal for remote fields without power, and ductile iron bodies withstand outdoor weather conditions.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025