Specification

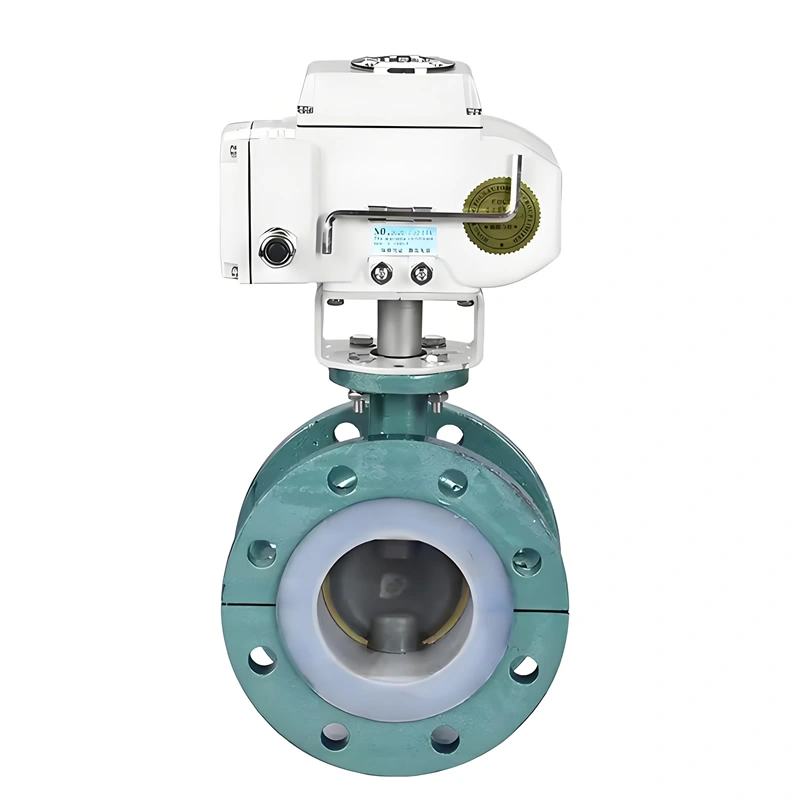

DN100~DN800 PN16 Cast Iron/Stainless Steel PTFE Seal Electric Flange Butterfly Valve

I. Product Overview

II. Key Attribute Parameters

- Size Range: DN100 ~ DN800, covering medium to large-diameter pipelines for industrial water distribution, process control, and drainage systems.

- Pressure Rating: PN1.6MPa, suitable for low to medium pressure loops such as boiler feedwater, hot water pipelines, and chemical transfer lines.

- Temperature Range: ≤200℃, compatible with PTFE seals to handle high-temperature media like steam and hot oil without seal degradation.

- Material Configuration:

- Body: Cast iron (QT450), WCB carbon steel, or stainless steel (1Cr18Ni9Ti)—cast iron for cost-effectiveness, stainless steel for corrosion resistance.

- Disc: QT450, WCB, or 1Cr18Ni9Ti, matching body material for structural consistency and wear resistance.

- Seal: PTFE (polytetrafluoroethylene) with flexible graphite backup, ensuring chemical resistance and tight sealing across temperature ranges.

- Stem: 1Cr18Ni9Ti stainless steel, resisting rust and ensuring smooth rotation under pressure.

- Actuator: Electric (FOSD series), with voltage options: DC12V~24V, AC12V, AC24V, AC110V, AC220V, AC380V; supports on-off, regulating, and intelligent control.

- Connection Type: Flange (per JIS, ASME, DIN, ISO standards), enabling leak-tight integration with pipeline flanges.

- Operation: 0~90° rotation, with rated travel time of 15/20/30S for precise flow adjustment; optional accessories include limit switches and positioners.

| Connection | Flange Type |

| Operating Pressure | PN1.6MPa |

| Control Mode | Electric Actuator |

| Rated Travel Time | 15/20/30S |

| Rotation Angle | 0-90° |

| Optional Voltage | DC12-24V AC12V AC24V AC110V AC220V AC380V |

| Body Material | Cast iron/WCB/Stainless steel |

| Structure | Butterfly valve |

|

Application |

Suitable for oxygen-containing corrosive media such as fresh water, live water, seawater, steam, food, medicine, various oils, |

FEATURE

1. Operating temperature range: -40°C-+95°C.

2. With excellent strength and toughness.

3. With excellent chemical resistance capabilities.

4. Retardant properties is the self-extinguishing.

5. Low thermal conductivity, about 1/200 of the steel.

6. The content of heavy ion in the medium up to the ultra-pure water standards.

7. Health indicators in line with national health standards.

8. Clean and smooth of the Tube wall, which can generate a smaller friction and adhesion when transferring fluid.

9.Light weight, the equivalent of 1/5 of steel, 1/6 of brass.

10. Easy to install. can be connected by flange, double union etc.

11.Excellent anti-aging and UV resistance, so that there is a great extension of the normal useful life than other piping systems.

Product Overview

III. Features Description

- PTFE Seal Reliability: PTFE’s chemical inertness resists water, oil, and mild acids/alkalis, while its low friction coefficient reduces wear during operation. The seal is reinforced with flexible graphite to maintain elasticity at high temperatures (≤200℃), achieving ANSI/FCI Class IV leakage (≤0.1% of flow)—critical for preventing media loss in water treatment or food processing.

- Electric Actuation Precision: The electric actuator offers programmable control (on-off/regulating), with position feedback to ensure accurate flow adjustment. Intelligent models support remote monitoring and automatic calibration, reducing manual intervention in large-scale systems like power plant steam loops.

- Flange Connection Stability: Flange design distributes pressure evenly across the valve body, avoiding leakage in high-pressure (PN1.6MPa) applications. It complies with multiple standards (JIS/ASME/DIN), simplifying integration into global projects without rework.

- Durable Structural Design: One-piece stem and disc reduce torque requirements, while stainless steel composite bearings ensure smooth rotation. The valve body undergoes anti-corrosion treatment (painting for cast iron, passivation for stainless steel), extending service life in humid or industrial environments.

- Wide Compatibility: Adaptable to diverse media (water, steam, oil, gas) and temperatures, with material options (cast iron for general use, stainless steel for corrosive media) to match application needs—eliminating the need for multiple valve types in complex systems.

IV. Manufacturing Processes

- Material Preparation: Cast iron/WCB/stainless steel castings undergo ultrasonic testing to detect internal defects. PTFE sheets are inspected for uniformity (no cracks or impurities) to ensure sealing performance.

- Body & Disc Machining: CNC lathes precision-machine valve bodies and discs to tight tolerances (±0.05mm), ensuring concentric alignment of the disc with the flow path. Flange faces are finished to Ra ≤1.6μm for leak-tight gasket sealing.

- Seal Assembly: PTFE seals are molded to match the valve’s inner diameter, then bonded to the body with high-temperature adhesive. Flexible graphite is layered behind the PTFE to enhance compression and sealing under pressure.

- Actuator Integration: Electric actuators are mounted via ISO5211 flanges, with stem-coupling alignment calibrated to ±0.5° to avoid jamming. Actuators undergo 5,000+ cycle tests to verify travel accuracy and torque output.

- Testing:

- Hydrostatic Test: Body tested at 2.4MPa (1.5×PN1.6) for 30 minutes; seat tested at 1.76MPa (1.1×PN1.6) with water to confirm no leakage.

- Operation Test: Actuator tested for travel time (15/20/30S) and position accuracy (±1°) to ensure consistent performance.

- High-Temp Test: Valve exposed to 200℃ for 2 hours, then operated to verify seal integrity and actuator functionality.

Valve Details

V. Product Advantages

- Superior Sealing Performance: PTFE seal with graphite backup ensures tight shut-off across temperatures, reducing leakage risks by 80% compared to rubber-sealed valves in high-temperature applications.

- Automated Efficiency: Electric actuation with remote control capability cuts manual operation costs by 40% in large systems (e.g., municipal water networks), while regulating models enable precise flow adjustment for process stability.

- Durability & Longevity: Corrosion-resistant materials and wear-resistant bearings extend service life to 10+ years in normal operation, reducing replacement frequency and downtime.

- Easy Installation & Maintenance: Flange connection simplifies alignment with pipelines, while modular design allows actuator replacement without removing the valve body—minimizing maintenance time.

- Cost-Effectiveness: Cast iron option offers affordability for general applications, while stainless steel provides corrosion resistance at a lower cost than exotic alloys—balancing performance and budget.

Application

VI. Application Fields

- Water Treatment: Controls raw water intake, treated water distribution, and sewage flow, with PTFE seals resisting chlorine and contaminants in municipal and industrial wastewater systems.

- Petrochemical Industry: Regulates oil, gas, and mild chemical transfer lines, leveraging stainless steel and PTFE to withstand hydrocarbons and low-concentration acids.

- Power Generation: Manages boiler feedwater, steam, and cooling water loops, with high-temperature tolerance (≤200℃) and PN1.6MPa pressure rating matching power plant requirements.

- Food & Beverage: Handles clean water, steam, and food-grade oils, with PTFE seals meeting hygiene standards (non-toxic, low adhesion) to avoid media contamination.

- Metallurgy: Controls cooling water and low-pressure steam in steel mills, with cast iron bodies resisting industrial dust and humidity.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025