Specification

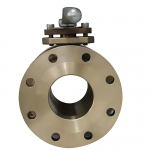

1/2″~24″ 150LB~2500LB Aluminum Nickel Bronze C95500 2PC Full Bore Flanged Floating Ball Valve

| Product Name | Aluminum Nickel Bronze C95500 2PC 4” Full bore Flanged Floating Ball Valve |

| Material | Stainless Steel/Duplex steel/Aluminium Bronze/Nickel-aluminum Bronze/Titanium Alloy, etc. |

| Size | 1/2″-24″(DN15-DN600) |

| Port | Full Port/Reduce Port |

| Working Pressure | 150LB-2500LB |

| Connection Ends | Flanged FF/RF/Rtj, Bw Ends |

| Working Temp. | -27ºC~220ºC |

| Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid |

| Operated | Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator. |

| Design standard | ISO 5208, API 6D |

| Inspection & Testing | According to API598 |

| Product Parameters |

| Design & Manufacture standard | API 608, API 6D, BS 5351, ASME B16.34 |

| Pressure & Temperature standard | API 608, API 6D, BS 5351, ASME B16.34 |

| Face to face dimension standard | ASME B16.10, API 6D |

| Ends Connection standard | ASME B16.5, ASME B16.47, ASME B16.25 |

| Test & Inspect standard | ISO 5208, API 6D |

| Testing Pressure(Mpa) |

| Pressure | 150LB | 300LB | 600LB | 900LB | 1500LB | 2500LB | |

| Strength Testing | 3.0 | 7.5 | 15.4 | 23.0 | 37.5 | 63.0 | Mpa |

| Seal Testing | 2.2 | 5.5 | 11.2 | 16.9 | 27.5 | 46.2 | |

| Air Testing | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

I. Product Overview

II. Key Attribute Parameters

- Size Range: 1/2″~24″ (DN15~DN600), covering small to large-diameter pipelines for diverse flow control needs.

- Pressure Range: 150LB~2500LB (2.0MPa~42.0MPa), adapting to low to ultra-high pressure systems such as offshore oil lines and high-pressure gas pipelines.

- Temperature Range: -27℃~220℃, with C95500 retaining toughness in cold environments and resisting oxidation at high temperatures.

- Material Configuration:

- Body & Ball: C95500 aluminum nickel bronze (含 Al 9~11%, Ni 4~5%), offering superior corrosion resistance to saltwater and chemicals.

- Seat: PTFE, PTFE+carbon fiber, or PPL—PTFE for general media, reinforced variants for high pressure/temperature.

- Stem: C95500 or stainless steel 316, with anti-blowout design to prevent ejection under pressure.

- End Connections: Flanged (FF/RF/RTJ) per ASME B16.5, ensuring leak-tight integration with pipelines.

- Actuation: Manual (handwheel/worm wheel), pneumatic, or electric—manual for simple on-off, automated options for remote control.

- Design & Test Standards: Design follows API 6D, API 608; testing complies with API 598, with hydrostatic strength tests at 1.5×rated pressure.

Product Overview

III. Features Description

- C95500 Corrosion Resistance: Aluminum nickel bronze forms a dense oxide layer, resisting saltwater corrosion (marine environments) and chemical erosion (acids, alkalis). This outperforms stainless steel in coastal or offshore applications, avoiding rust-related jamming.

- 2PC Structure & Full Bore: The two-piece body (bolted connection) balances structural strength and maintenance accessibility—internal components can be inspected without full disassembly. Full bore design matches pipeline diameter, minimizing pressure drop and enabling unobstructed media flow (critical for viscous oil or slurry).

- Floating Ball Sealing: The ball “floats” against the seat under media pressure, ensuring uniform sealing contact. This self-adjusting design compensates for minor pipeline misalignment, achieving ANSI/FCI Class VI leakage (near-zero) even under pressure fluctuations.

- Versatile Seating Options: PTFE seats handle general media (-27℃~180℃), while PTFE+glass fiber or PPL seats extend service to 220℃ and high pressure (2500LB), adapting to steam or hot oil applications.

- Flange Compatibility: RF/RTJ flanges comply with ASME B16.5, fitting seamlessly into global pipelines. RTJ flanges are ideal for high-pressure systems (900LB+), preventing leakage in gas or oil transmission.

IV. Manufacturing Processes

- Material Validation: C95500 castings undergo spectral analysis to verify alloy content (Al, Ni, Cu) and ultrasonic testing to detect internal defects. Charpy impact tests confirm toughness at -27℃.

- Precision Casting: The body and ball are investment-cast to achieve tight tolerances (±0.05mm), ensuring the ball rotates smoothly without jamming. Cast surfaces are sandblasted to remove impurities.

- CNC Machining: Ball and seat sealing surfaces are CNC-ground to Ra ≤0.8μm, ensuring uniform contact. Flange faces are machined to ASME B16.5 dimensions, with bolt holes aligned to ±0.5mm for easy installation.

- Assembly & Testing:

- Hydrostatic Test: Body tested at 1.5×rated pressure (e.g., 3.0MPa for 150LB) for 30 minutes; seat tested at 1.1×rated pressure with water to confirm no leakage.

- Air Leak Test: 0.6MPa air test ensures stem packing and flange gaskets are leak-tight.

- Operation Test: 100+ open/close cycles verify smooth rotation, with focus on floating ball sealing under pressure.

Valve Details

V. Product Advantages

- Superior Corrosion Resistance: C95500 extends service life to 15+ years in marine and chemical environments—50% longer than 316 stainless steel valves in saltwater applications.

- High-Pressure Durability: 2500LB rating and two-piece structure withstand extreme pressure, making it suitable for offshore oil platforms and high-pressure gas pipelines.

- Low Energy Loss: Full bore design reduces pressure drop by 30% vs. reduced-bore valves, lowering pumping costs in large-scale water or oil transfer systems.

- Easy Maintenance: 2PC structure allows seat/ball replacement without removing the valve from the pipeline, cutting maintenance downtime by 40% vs. one-piece valves.

- Global Compliance: API 6D and ASME certifications enable use in international projects, avoiding rework for standard mismatches.

Application

VI. Application Fields

- Marine Industry: Used in ship ballast, bilge, and seawater cooling systems—C95500 resists saltwater corrosion, preventing valve failure in offshore environments.

- Oil & Gas: Controls crude oil and natural gas flow in onshore/offshore pipelines, with high-pressure ratings (2500LB) handling transmission pressures.

- Water Treatment: Regulates treated water and wastewater flow, with corrosion resistance to chlorine and cleaning agents ensuring long-term reliability.

- Chemical Processing: Manages mild acids, alkalis, and solvents in reaction lines—PTFE seats resist chemical attack, while C95500 avoids material contamination.

- Power Generation: Controls steam and cooling water flow in power plants, with high-temperature seats (PPL) adapting to 220℃ steam.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025