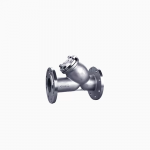

Product Overview

- Named after its configuration, the Y-filter is a device that mechanically removes unwanted solids from liquid, gas, or vapor lines by means of perforated or wire mesh filter elements. Y-filters are a very cost-effective filtration solution in many applications where the amount of material removed from the fluid is relatively small, resulting in long intervals between screen cleanings. Filter screens are cleaned manually by shutting down the line and removing the filter cover.

Although the Y-filter is often used in many different types of fluid applications, it is considered standard for steam applications and is almost universally used in these applications. Its compact cylindrical shape is very robust and can withstand high pressures. It is literally a pressure vessel. It is not uncommon to find Y-filters that can handle pressures up to 6,000 psi. - In addition to steam, Y-filters are often used in air or natural gas applications. Here, high pressures are not uncommon. However, unlike steam, high air pressure does not automatically mean high temperatures, so a plain carbon steel body with adequate wall thickness is usually sufficient.

- Unlike other types of filters, Y-filters have the advantage that they can be installed either horizontally or vertically. Obviously, in both cases, the screening element must be located on the “lower” side of the filter body so that the trapped material can be correctly collected in it.

- Some manufacturers reduce the size of the Y-filter body to save material and reduce costs. Before installing a Y-filter, make sure it is large enough to properly handle the flow.

- Inexpensive filters may indicate undersized equipment.

- Stainless steel Y-filters are used where high corrosion resistance or non-contamination is required. They are popular in the chemical, food and pharmaceutical industries.

- Y-strainers are available with a variety of end connections, including threaded, flanged, and welded.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025