Specification

Ball Valve Detail Information:

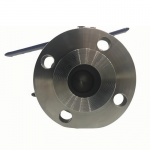

| Name | double block and bleed DBB ball valve with bleed valve |

| Model Number: | TIANYUQ41F-PN16-DN15 |

| Standard or Nonstandard: |

ISO 17292 |

| Structure: | TIANYU ball valve |

| Pressure: | PN16 |

| Power: | Lever Operated |

| Material: | Stainless steel ball valve |

| Temperature of Media: | -29 Deg. C ~ 150 Deg. C |

| Media: | Crude Oil, Natural Gas, etc |

| Port Size: | full bore |

| Application: | water, steam, oil, etc |

| OEM | We offer OEM service |

Ball Valve Optional Material: (for future reference only)

| Carbon steel | ASTM A105 , etc |

| Low temperature steel | A350 Gr. LF2 , etc |

| Cr-Mo steel | A182 Gr. F11 , F22 , etc |

| Stainless Steel | A182 Gr. F304 , F304L , F316 , F316L , F321 , F347 , etc |

| Alloy steel | Alloy 20 , etc |

| Super duplex | A182 Gr. F51 , F53 , F55 , etc |

| Aluminum bronze | B148 C95500 , C95600 , C95800 , etc |

| Monel | Monel K400, K500 |

| Inconel | inconel 600 , etc |

| Hastelloy | Hastelloy B , Hastelloy C276 , etc |

| Incoloy | Incoloy 825 , Incoloy 625 , etc |

Product Overview

I. Core Product Features

II. Key Attributes and Technical Parameters

(A) Structural and Functional Design

- Trunnion-Supported Structure:

The ball is supported by upper and lower trunnions, reducing stem load (operation torque decreased by 30%) and enhancing sealing stability under high pressure. Trunnions and the ball are integrally forged and ultrasonically tested (UT) to ensure no internal defects. - Double Block and Bleed (DDB) Function:

Provides bidirectional bubble-tight sealing (leakage rate ≤5×10⁻¹⁰Pa·m³/s), capable of blocking upstream and downstream media simultaneously while safely releasing cavity pressure through the bleed port. Complies with API 598 Class IV sealing standards, meeting safety requirements for hot work and online maintenance. - High-Pressure Adaptation:

Meets ASME B16.34 standards, with pressure ratings from 150LB to 2500LB (PN16–PN420), supporting a maximum pressure of 42MPa for Class 2500 high-pressure pipeline systems.

(B) Material and Application Compatibility

| Component | Standard Materials | Special Application Materials | Applicable Media | Temperature Range |

|---|---|---|---|---|

| Body/Ball | A182 F304, F316 Stainless Steel | F316L (low-carbon), F347 (intergranular corrosion-resistant) | Natural gas, crude oil, steam, acid | -29℃~427℃ |

| Seat/Seal | RTFE (reinforced PTFE) | PEEK (polyetheretherketone, 260℃ resistance) | High-temperature oil, chemical solvents | -40℃~260℃ |

| Stem | A182 F6NM (martensitic SS) | Inconel 718 (superalloy) | Particle-laden media, high-vibration | -196℃~650℃ |

| Fasteners | A193 B8 (stainless steel bolts) | A193 B8M (corrosion-resistant bolts) | Marine environments, strong corrosives | -162℃~540℃ |

(C) Key Performance Parameters

- Size Range: 1/2″–10″ (DN15–DN250), full-bore design with flow coefficient ≤0.7 (DN100 model);

- Operation Modes: Manual (standard handwheel), electric, pneumatic (optional), with manual operation torque ≤200N·m (DN100/2500LB);

- Surface Treatment: Polished interior/exterior (Ra≤1.6μm), optional epoxy coating (300μm thickness, 2000-hour salt spray test) for marine applications;

- Certifications: ISO 9001, CE-PED, EAC certified, with customization support for API 6D, NACE MR0175 (sulfur-resistant), etc.

III. Manufacturing Processes and Standards

(A) Precision Forging Technology

- Integral Forging:

Body and ball forged using a single-piece die (forging ratio ≥5:1) on a 2000-ton press, achieving ASTM No.8+ grain size for uniform material density and 40% improved impact resistance. - High-Precision Machining:

- 5-axis CNC machining centers mill seat sealing surfaces to ≤0.003mm flatness and Ra≤0.8μm roughness;

- Ball ground with CNC grinders to ≤0.005mm roundness, ensuring ≤0.01mm fit clearance with seats for zero-leakage sealing.

(B) Full-Process Quality Control

- Pressure Testing:

- Strength Test: 1.5x rated pressure (water, 30-minute hold) with no deformation or leakage;

- Seal Test: 1.1x rated pressure (gas/water), bidirectional testing with leakage rate ≤0.1cc/min;

- Cryogenic Test: Operation tested at -46℃ to ensure reliability in low-temperature conditions.

- Nondestructive Testing:

- 100% ultrasonic testing (UT) for body and trunnions, sensitivity ≥Φ1.2mm;

- Radiographic testing (RT) for welds, compliant with ASME BPVC Section VIII.

Features:

Piping and instrument valves in one body

Weight, space and cost saving over traditional designs

Blowout-proof valve stems and needles

Complete traceability of materials

1/4 female NPT standard vent with plug

1/2 female NPT standard outlet with plug

Details:

1.Maximum working pressure:6000 psig

2.Working temperature up to 1200°F ( 649°C ) with Graphite packing

3.Colour coded valve function identification

4.Fire-tested design in accordance with BS 6755 part 2

5.Flanged connections comply with ANSI B16.5 RF and RTJ

6.Pressure ratings in accordance with ANSI B16.34

7.Every design is hydraulic pressure tested in accordance with EN 12266-1 and API 598

8.Every set is tested with nitrogen for leak-tight performance at 6000 psig

Valve Details

Application Scenarios and Industry Value

(A) Typical Applications

- Oil & Gas Industry:

- Wellhead Equipment: 2500LB high-pressure valves for shale gas extraction, sulfur-resistant materials (NACE MR0175 certified) suitable for ≤1500ppm H₂S, 8-year service life;

- Long-Distance Pipelines: DDB function enables pipeline section isolation for live tapping and online pigging, reducing downtime by ≥50%.

- Chemical & Petrochemical Industry:

- Reactor Inlet/Outlet Control: Rapid media shut-off in polymerization reactions to prevent backflow hazards;

- High-Temperature Steam Systems: F321 stainless steel valves withstand 540℃, reducing leakage incidents by 90% in heat exchangers.

- Power & Energy Sector:

- Supercritical Power Plants: 2500LB valves for main steam pipelines (25MPa, 540℃), passing 100,000 load cycles with sealing retention ≥95%;

- LNG Terminals: Cryogenic valves (-162℃) with F316L stainless steel and low-temperature RTFE seals ensure zero leakage in LNG transport.

(B) Customer Value Enhancement

- Safety: DDB function eliminates cavity overpressure risks, complying with OSHA standards for confined space operations;

- Maintenance Efficiency: Trunnion structure reduces stem wear, extending maintenance intervals from 6 months to 1 year, cutting costs by 40%;

- Customization Flexibility: Supports non-standard sizes, special connections (butt weld, socket weld), and explosion-proof actuators (ATEX certified) for complex applications.

TIANYU Brand Services and Commitments

- Rapid Delivery: Standard models shipped within 7 days, customized products within ≤20 days, 800 units/month production capacity;

- Lifecycle Support: Installation guidance, annual inspections, and cavity cleaning services, 3-year warranty (under normal use);

- Sustainable Design: 98% recyclable components, 35% lower forging energy consumption than casting, compliant with EU CE PED environmental directives.

Application

The TIANYU ASME 2500LB Stainless Steel Forged Trunnion Double Block and Bleed Ball Valve combines “high-pressure reliability and safety efficiency,” integrating precision forging with intelligent design to deliver robust fluid control solutions for global industries. Whether in high-pressure gas fields, high-temperature chemical plants, or cryogenic energy systems, TIANYU empowers clients with safe operations and performance optimization through professional technology and global services.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025