Specification

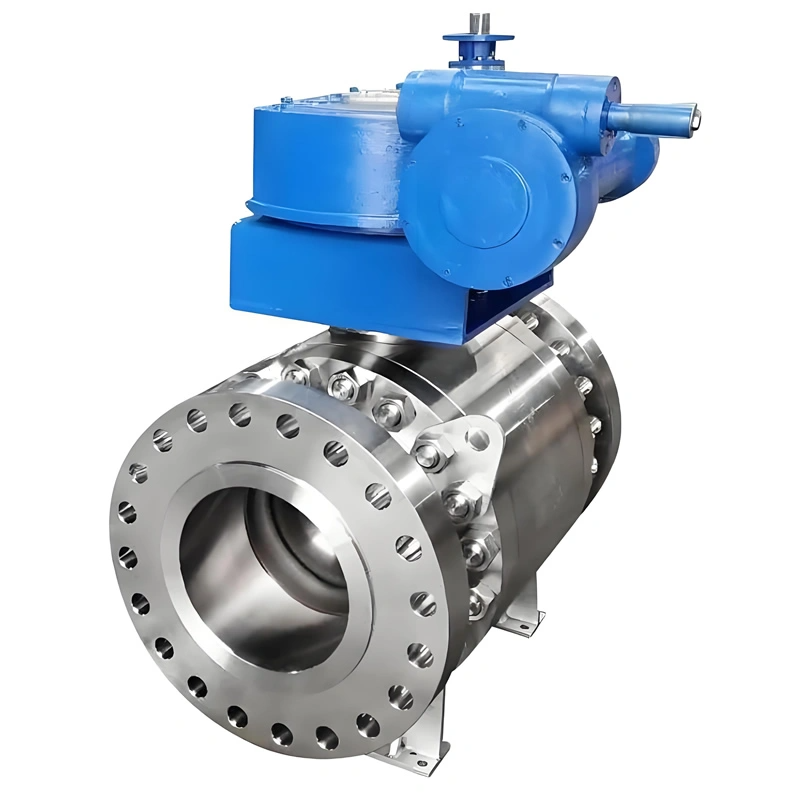

DN300 900lb 3-Piece F304L Stainless Steel Trunnion Mounted Flanged Ball Valve (API 608, Steam Rated)

I. Product Overview

II. Key Attribute Parameters

- Size: DN300 (12″), suitable for large-diameter pipelines requiring high flow capacity.

- Pressure Rating: 900lb (15.0MPa), adapting to high-pressure systems such as steam transmission and industrial process pipelines.

- Temperature Adaptability: Steam-rated (compatible with high-temperature media, typically up to 232℃ or higher based on sealing materials), with F304L retaining stability under thermal cycling.

- Material Configuration:

- Body & Ball: F304L stainless steel, offering excellent corrosion resistance to steam, water, and mild chemicals; low carbon content prevents intergranular corrosion in high-temperature environments.

- Seat: Molon (high-temperature resistant material), ensuring tight sealing under high pressure and temperature without degradation.

- Trunnion & Stem: F304L stainless steel, with trunnions supporting the ball to eliminate movement; stem designed for anti-blowout safety.

- End Connections: Flanged (per ASME B16.5), ensuring leak-tight integration with high-pressure pipelines.

- Actuation: Gearbox operation, reducing torque required to operate large-diameter valves, enabling smooth manual control even under high pressure.

- Design & Test Standards: Design follows API 608, ASME B16.34; testing complies with API 598 (hydrostatic strength test at 1.5×rated pressure) and fire safety per API 607.

Product Overview

III. Features Description

- Trunnion Mounted Stability: The ball is fixed by upper and lower trunnions, transferring fluid pressure loads to the trunnion bearings instead of the seat. This eliminates ball displacement even at 900lb pressure, avoiding seat wear and ensuring consistent sealing—critical for high-pressure steam systems where leakage risks energy loss or safety hazards.

- 3-Piece Structure: The valve body splits into three bolted sections (two end caps + middle section), allowing easy disassembly for maintenance. Internal components (ball, seat, trunnions) can be inspected or replaced without removing the valve from the pipeline, reducing downtime in critical systems.

- High-Temperature Sealing: Molon seats retain elasticity at high temperatures, maintaining tight contact with the ball to achieve ANSI/FCI Class VI leakage (near-zero). For fire safety, a fireproof sealing ring between the ball and seat forms a metal-to-metal backup seal if the soft seat degrades, meeting API 607 standards.

- Gearbox Operation: The integrated gearbox reduces operating torque by 50% compared to direct manual operation, making it feasible to control DN300 valves under high pressure. This ensures smooth, precise actuation without excessive force, extending service life of stem and seals.

- F304L Corrosion Resistance: F304L stainless steel resists corrosion from steam condensate, water, and mild chemicals, avoiding rust-related jamming or leakage. Its low carbon content prevents intergranular corrosion in high-temperature, high-humidity environments—common in steam systems.

IV. Manufacturing Processes

- Material Validation: F304L stainless steel undergoes spectral analysis to verify chemical composition (Cr ≥18%, Ni ≥8%, C ≤0.03%) and ultrasonic testing to detect internal defects, ensuring corrosion resistance and structural strength.

- Precision Forging & Machining: Body and ball are forged from F304L to eliminate internal pores, then CNC-machined to tight tolerances (±0.03mm). The ball’s sealing surface is ground to Ra ≤0.8μm for uniform contact with the seat; trunnion bearings are machined for smooth rotation.

- Assembly & Trunnion Integration: Trunnions are press-fitted into the body and welded for stability; seats are pre-loaded with springs to compensate for wear. A torque test confirms the gearbox operates smoothly with the stem, with 50+ open/close cycles verifying no jamming.

- Testing:

- Hydrostatic Test: Body tested at 22.5MPa (1.5×900lb) for 30 minutes to check for structural leaks; seat tested at 16.5MPa (1.1×900lb) with water to confirm no leakage.

- High-Temperature Test: Valve is heated to steam-rated temperatures, operated 100+ cycles to verify seat sealing and trunnion stability under thermal expansion.

- Fire-Safe Test: API 607 compliance verified by exposing the valve to 750℃ fire, then testing for post-fire sealing integrity.

Valve Details

-

Corrosion & High-Temp Resistance

Forged from F304L stainless steel, it resists steam, water and mild chemicals. Low carbon (≤0.03%) prevents intergranular corrosion, stable at 232℃ for high-temp pipelines.

-

High-Pressure Stable Structure

Trunnion-mounted ball design fixes the ball, withstanding 900lb pressure. 3-piece body enables easy maintenance without pipeline removal, ideal for DN300.

-

Reliable Sealing System

Molon seats achieve ANSI/FCI Class VI leakage. Spring compensation offsets wear. API 607 fire-safe, with metal backup seal for emergencies.

-

Convenient & Efficient Operation

Gearbox reduces operating force by 50%. Hardened gears with lubrication ensure smooth operation, enabling precise 90° ball positioning.

V. Product Advantages

- High-Pressure Reliability: Trunnion design and F304L construction withstand 900lb pressure, reducing failure risks in steam transmission—where pressure surges are common.

- Corrosion Resistance: F304L avoids rust and intergranular corrosion, extending service life to 15+ years in steam and chemical environments—twice that of carbon steel valves.

- Easy Maintenance: 3-piece structure allows in-line component replacement, cutting maintenance downtime by 40% vs. one-piece valves. Gearbox components are modular for quick repairs.

- Fire & Safety Compliance: API 607 fire safety certification ensures sealing integrity in fire emergencies; anti-blowout stem design prevents ejection under pressure, meeting industrial safety standards.

- Energy Efficiency: Tight sealing (Class VI leakage) reduces steam or media loss, lowering energy waste by 20% in high-pressure systems compared to standard valves.

Application

VI. Application Fields

- Power Generation: Controls superheated steam flow in boiler and turbine auxiliary systems, with high-pressure rating and temperature resistance adapting to steam conditions (up to 232℃) and F304L resisting condensate corrosion.

- Petrochemical Industry: Manages high-pressure hydrocarbon or process steam flow in refineries, leveraging corrosion resistance to avoid chemical attack and trunnion stability to handle pressure fluctuations.

- Industrial Steam Systems: Regulates steam flow in large-scale heating or manufacturing processes (e.g., paper, textile mills), with gearbox operation ensuring easy control of large-diameter pipelines.

- Chemical Processing: Handles high-pressure, high-temperature chemical reactants or heating media, with F304L resisting corrosion from process fluids and tight sealing preventing contamination.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025