Specification

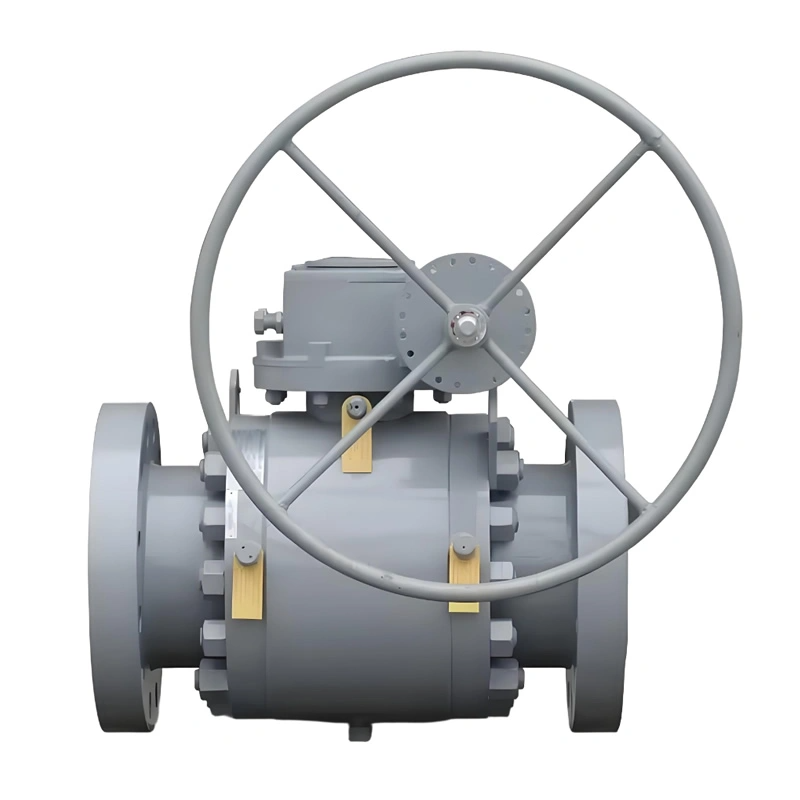

TIANYU API Carbon Steel Trunnion Ball Valve – High Pressure

I. Product Overview

II. Key Attribute Parameters

-

Specifications and Sizes:

- Size range: 2in-24in (DN50-DN600), covering medium and large pipeline needs;

- Structural dimensions: For 6in Class 150, length 394mm, height 280mm (specific dimensions increase with size and pressure class, complying with ANSI B 16.34).

-

Pressure and Temperature:

- Pressure class: Class 150/300/400/600/800/900/1500/2500 (1.6-42MPa), suitable for low to ultra-high pressure systems;

- Test pressure: Shell hydrostatic test at 1.5×nominal pressure, seat test at 1.1×nominal pressure, no leakage under pressure;

- Medium temperature: -29℃~425℃ (depending on sealing material), withstanding low-temperature LNG to high-temperature steam.

-

Materials and Sealing:

- Body material: Carbon steel WCB (ASTM A216), tensile strength ≥485MPa, suitable for high-pressure conditions;

- Ball material: 304 stainless steel (CF8), precision-ground surface with roundness error ≤0.01mm;

- Sealing material: PTFE (normal temperature), VITON (high temperature), ensuring bubble-tight sealing (leakage rate ≤0.1×10⁻⁶ mL/s);

- Seat: Spring-loaded structure to compensate for sealing gaps caused by temperature and pressure changes.

-

Connections and Standards:

- Connection types: RF flange, RTJ flange, butt-weld (BW), adapting to different pipeline systems;

- Design standards: API 6D, ANSI B 16.34;

- Test standard: API 598;

- Certifications: CE, SGS, ISO 9001, meeting international industrial safety regulations.

Product Overview

III. Structural Features and Design Advantages

-

Trunnion Ball Stability: The ball is fixed by upper and lower shafts, avoiding ball displacement caused by medium pressure, reducing seal face wear. Its service life is over twice that of floating ball structures, especially suitable for high-pressure conditions (Class 600 and above).

-

Three-Piece Easy Maintenance: The valve body consists of left, middle, and right sections connected by bolts. During maintenance, there is no need to disassemble the entire pipeline—only the middle section needs to be split to replace seals or the ball, reducing maintenance time by 50%.

-

Safety Protection Design:

- Anti-static device: 316L stainless steel spring connects the ball and valve body to discharge static electricity (resistance ≤10⁶Ω), preventing sparks from causing hazards;

- Fire-safe structure: The seat uses graphite backup sealing, maintaining basic sealing after fire, complying with API 607 fire safety standards;

- Anti-blowout stem: The stem has an inverted seal structure at the bottom to prevent stem blowout under high pressure, enhancing system safety.

-

Wide Working Condition Adaptability: The spring-loaded seat automatically compensates for sealing gaps caused by temperature changes, maintaining stable sealing within -29℃~425℃; optional seal materials adapt to corrosive (VITON) or sanitary (PTFE) media.

IV. Manufacturing Processes and Quality Control

-

Material Selection and Forging:

ASTM A216 WCB carbon steel billets are selected, with chemical composition verified by spectral analysis (C≤0.30%, Mn≤1.00%) to ensure mechanical properties; the ball is forged from 304 stainless steel (forging ratio ≥3) to eliminate internal defects, with tensile strength ≥520MPa. -

Precision Machining and Grinding:

- Valve body: Integrally machined by CNC lathe, with flow channel inner wall roughness Ra≤1.6μm to reduce medium turbulence;

- Ball: Machined by high-precision grinder, roundness ≤0.01mm, surface roughness Ra≤0.8μm to ensure seal face fit;

- Flange: RF/RTJ seal faces are precision-machined by vertical lathe, flatness error ≤0.05mm, complying with ANSI B 16.5.

-

Assembly and Testing:

- Seat pre-assembly: Spring-loaded seats are tested for tightness under 1.5×working pressure to ensure no leakage;

- Overall testing: Each valve passes API 598 tests: shell hydrostatic test for 30 minutes without leakage, gas tightness test (0.6MPa nitrogen) with no bubbles;

- Non-destructive testing: 100% penetrant testing (PT) for key welds, and radiographic testing (RT) for high-pressure models.

-

Surface Treatment:

Carbon steel valve bodies are sprayed with anti-rust paint (dry film thickness ≥80μm); stems undergo nitriding treatment (hardness ≥800HV), passing a 1000-hour salt spray test to adapt to harsh environments.

Valve Details

V. Core Product Advantages

-

High Pressure Resistance and Long Life: Trunnion ball structure + WCB carbon steel body enables long-term operation under Class 2500 (42MPa) pressure, reducing seal face wear by 30% with a service life of over 15 years.

-

Safety Compliance: Integrating anti-static, fire-safe, and anti-blowout designs, passing API 607 and CE certifications, meeting safety requirements of high-risk industries such as petroleum and natural gas.

-

High Maintenance Efficiency: The three-piece design reduces seal replacement time to 2 hours (traditional one-piece requires 8 hours), lowering downtime losses.

-

Full Working Condition Adaptability: -29℃~425℃ temperature range + multiple seal material options, directly applicable to LNG low-temperature pipelines, high-temperature steam systems, and weakly corrosive media scenarios.

-

International Standard Compatibility: Sizes and pressure classes fully comply with API 6D and ANSI standards, enabling direct replacement of imported brands without adjusting pipeline layouts, reducing project adaptation costs.

Application

VI. Application Fields and Scenarios

-

Petroleum and Natural Gas:

- Wellhead Christmas trees: Control high-pressure crude oil flow, with trunnion ball structure withstanding frequent opening/closing wear;

- Natural gas pipelines: RTJ flange connections ensure no leakage under high pressure, anti-static design avoids explosion risks.

-

Chemical and Petrochemical:

- Reactor feed pipelines: Class 600 pressure class adapts to high-pressure reaction media, PTFE seals prevent chemical corrosion;

- Hot oil transportation systems: VITON seals withstand 300℃ high temperatures, ensuring no thermal oil leakage.

-

Power and Energy:

- Power plant steam pipelines: Class 300 controls high-temperature steam (425℃), fire-safe structure enhances system safety;

- Nuclear power auxiliary systems: Stainless steel internal parts resist radiation, meeting harsh environment requirements.

-

Municipal and Industrial:

- High-pressure water supply pump stations: Large-size (24in) models control main water transmission pipelines, with rapid shut-off function for emergency conditions;

- LNG receiving terminals: Maintain sealing under low-temperature conditions (-162℃), ensuring safe LNG transportation.

TIANYU three-piece trunnion ball valve, 2-24in, Class 150-2500, WCB carbon steel + 304 ball, adapts to multiple media. Trunnion ball stable, three-piece easy to maintain, meets API standards. Ideal for petroleum, power high-pressure systems, safe and durable.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025