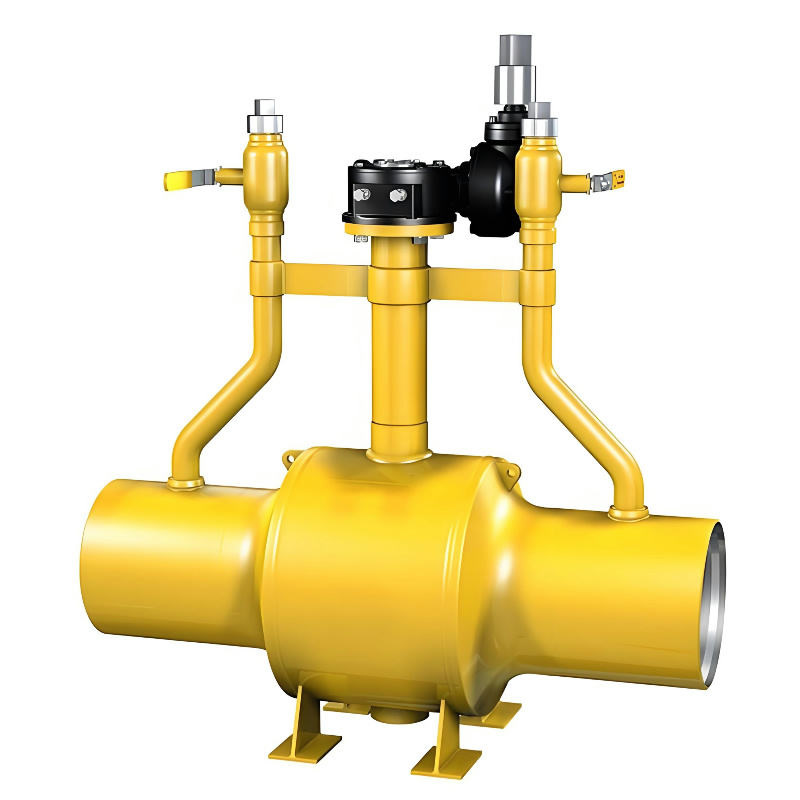

TIANYU API ASME BS DIN API6D DN15-DN1000 Carbon Steel SS Wcb CF8 Anti-Explosion Ball Valve for Petroleum Oil Gas

I. Product Overview

II. Key Attributes and Specification Parameters

Basic Design and Dimensional Attributes

- Valve Type: 2-way floating ball valve, quarter-turn operation; available in full-bore (FB) or reduced-bore (RB) configurations. Full-bore design ensures unobstructed flow and pigging compatibility per API 6D mandates .

- Nominal Diameter Range: DN15-DN1000; compatible with pipeline systems of varying scales, from medium-duty industrial lines to large-volume gas distribution networks .

- Pressure Rating: Class 150, Class 300 (ANSI); PN16, PN50 (DIN); designed to withstand system pressures up to 5.0 MPa (725 psi) for Class 300 models .

- End Connection: Flanged (RF/RTJ) per ASME B16.5 (NPS 1½ to 24) and DIN EN 1092-1 (PN16/PN50); raised face (RF) as standard for general applications, ring type joint (RTJ) optional for high-pressure services .

- Face-to-Face Dimensions: Compliant with API 6D (long/short pattern) and ASME B16.10; ensures interchangeability with valves from other manufacturers .

Material Specifications

- Body and Bonnet: ASTM A216 WCB cast carbon steel (primary); optional low-temperature grades (ASTM A352 LCB for -46℃ service) or stainless steel (ASTM A351 CF8/CF8M) for corrosive media . WCB offers tensile strength ≥485 MPa and excellent impact resistance after normalizing heat treatment .

- Ball and Stem: Ball: ASTM A182 F316 stainless steel (corrosion resistance); Stem: ASTM A182 F316 stainless steel with blowout-proof design to prevent ejection under pressure .

- Seat and Seal Materials:

- Soft Seats: PTFE, PPL (polyphenylene sulfide); suitable for temperatures -29℃ to 180℃, providing API 598 Class VI bubble-tight shutoff .

- Metal Seats: 316 stainless steel; for high-temperature applications up to 425℃, meeting API 598 Class IV leakage requirements .

- Packing and Gasket: Graphite packing with corrosion inhibitor; spiral-wound gaskets (316 stainless steel core with graphite filler) for flanged connections .

Performance and Operational Parameters

- Temperature Range: -29℃ to 425℃ (WCB body with metal seats); -29℃ to 180℃ (soft seats) .

- Leakage Class: API 598 Class VI (soft seats); Class IV (metal seats) .

- Actuation Options:

- Manual: Worm gear operator (20:1 ratio) with torque indicator and locking device .

- Automated: Electric actuator (AC220V/110V, DC24V) or pneumatic actuator (5-6 bar air supply); optional smart positioners for 4-20mA proportional control .

- Cycle Life: ≥50,000 operations for manual valves; ≥100,000 cycles for automated models .

- Safety Features: Anti-static device (≤10Ω resistance between ball and body); fire-safe design per API 607 (30-minute fire test with maintained sealing); optional DBB (double block and bleed) functionality .

Testing and Certification

- Design Standards: API 6D, ASME B16.34, ANSI B16.5, BS 5351, DIN EN 12516-3 .

- Testing Standards: API 598 (shell, seat, backseat tests); API 6D (drift test for full-bore models); fire test per API 607 .

- Hydrostatic Testing: Shell test: 1.5× nominal pressure (e.g., 375 psi for Class 150); Seat test: 1.1× nominal pressure .

- Certifications: ISO 9001 quality management; API 6D product certification; ATEX/IECEx optional for hazardous area deployment .

Product Overview

III. Product Features

- API 6D-Compliant Pipeline Readiness: The full-bore design accommodates pipeline pigs for cleaning and inspection, eliminating flow restrictions and ensuring system maintainability . Automatic cavity pressure relief prevents dangerous pressure buildup when trapped media expands due to temperature fluctuations—a critical safety feature for gas and volatile liquid service .

- Dual-Seal Adaptability: Soft PTFE/PPL seats deliver bubble-tight shutoff (API 598 Class VI) for clean media like natural gas or refined oil, reducing fugitive emissions and meeting environmental regulations such as EPA’s Methane Emission Reduction Program . Metal seats (316 stainless steel) withstand high temperatures and abrasive media, maintaining sealing integrity in steam lines or crude oil applications with minor particulates .

- Enhanced Safety Systems: The fire-safe design activates a secondary metal-to-metal seal if soft seats degrade during combustion, ensuring the valve remains leak-tight for 30 minutes per API 607 . An anti-static spring bridges the ball and body, dissipating electrostatic charges to prevent ignition in flammable environments . Optional DBB functionality isolates upstream and downstream pressure sources and vents cavity media, simplifying maintenance and leak detection .

- Robust Material Performance: WCB carbon steel undergoes normalizing heat treatment (850–900℃, air-cooled) to relieve internal stress and eliminate casting defects like porosity, ensuring structural integrity under Class 300 pressure . The 316 stainless steel ball and stem resist pitting corrosion from moisture and mild chemicals, extending service life in coastal or humid environments .

- Versatile Actuation and Control: Manual worm gear operators reduce torque requirements, enabling easy operation even for large-diameter valves (DN200) . Electric and pneumatic actuators support remote control via SCADA systems, ideal for pipeline networks where on-site access is limited . Smart positioners (optional) provide precise flow modulation for process optimization in refineries or chemical plants .

- Global Interchangeability: Compliance with ASME B16.5 (flanges), API 6D (dimensions), and DIN standards ensures the valve integrates seamlessly into international projects—eliminating the need for custom adapters or modifications . Multi-standard compatibility reduces inventory costs for global operators .

IV. Manufacturing Process

- 1. Raw Material Sourcing and Inspection: WCB carbon steel ingots and 316 stainless steel blanks are sourced from certified suppliers and tested to verify compliance with ASTM standards. Chemical composition analysis (via optical emission spectrometry) confirms WCB’s carbon content (0.25–0.35%) and 316’s chromium (≥16%) and molybdenum (≥2%) levels . Mechanical testing (tensile, hardness) validates WCB’s tensile strength (≥485 MPa) and 316’s yield strength (≥205 MPa) .

- 2. Valve Body and Bonnet Casting: WCB body and bonnet are produced via sand casting with resin-bonded molds to ensure dimensional accuracy. The casting process incorporates risers to prevent shrinkage defects, and all castings undergo non-destructive testing (NDT) including ultrasonic testing (UT) and liquid penetrant testing (PT) to detect internal porosity or cracks .

- 3. Heat Treatment: Cast WCB components are normalized at 880℃ (held for 1 hour) and air-cooled to relieve internal stress and enhance impact resistance. 316 stainless steel ball and stem blanks undergo solution annealing (1050–1100℃) and water quenching to restore corrosion resistance .

- 4. CNC Precision Machining: Critical surfaces are machined using 5-axis CNC centers to achieve tight tolerances (±0.05mm). Flange faces are milled to ASME B16.5 RF/RTJ specifications, with bolt holes drilled via coordinate measuring machine (CMM) for alignment . The ball is ground to a mirror finish (Ra ≤0.8μm) to ensure uniform contact with seats, minimizing friction and leakage .

- 5. Seat Preparation and Installation: Soft seats (PTFE/PPL) are compression-molded to match seat groove dimensions and bonded with high-temperature adhesive to prevent displacement. Metal seats (316) are precision-ground to Ra ≤0.4μm and press-fitted into the valve body, with laser welding for permanent attachment .

- 6. Stem and Packing Assembly: The 316 stem is inserted into the bonnet, with a multi-layer graphite packing gland compressed to form a gas-tight seal. A blowout-proof retainer secures the stem, preventing ejection under pressure . An anti-static spring is installed between the stem and body to ensure electrical continuity .

- 7. Ball and Valve Core Integration: The 316 ball is mounted on the stem, with guided alignment to ensure the ball’s bore aligns with the flow path when open. The bonnet is bolted to the body using ASTM A320 L7 alloy steel bolts, torqued to ASME B16.34 specifications .

- 8. Actuator Mounting: For automated models, electric/pneumatic actuators are mounted via ISO 5211 brackets. The actuator’s drive shaft is coupled to the valve stem, with torque calibration (50–200 N·m, depending on valve size) to prevent motor overload . Manual worm gear operators are assembled with position indicators and locking devices .

- 9. Pressure Testing (API 598/6D):

- Shell Test: The valve body is filled with water and pressurized to 1.5× nominal pressure for 10 minutes. No leakage or deformation is allowed, verified via ultrasonic leak detectors .

- Seat Test: Gas (0.6 MPa nitrogen) is applied to the inlet, with leakage measured using a bubble counter. Soft-seated valves must meet API 598 Class VI (≤0.15 mL/min for DN100), while metal-seated models comply with Class IV .

- Backseat Test: The stem packing is tested at 1.5× nominal pressure to ensure no leakage between the stem and bonnet .

- 10. Fire-Safe and Anti-Static Testing: Valves with fire-safe design undergo API 607 testing—exposed to 750–800℃ flame for 30 minutes, then cooled and tested for leakage . Anti-static performance is verified with a resistance tester (≤10Ω) .

- 11. Surface Treatment: WCB components are shot-blasted to Sa2.5 standard, then coated with two layers of epoxy paint (dry film thickness ≥120μm) for corrosion resistance. Stainless steel parts are passivated in nitric acid to enhance rust protection .

- 12. Final Inspection and Documentation: Each valve undergoes dimensional verification via CMM, with laser marking applied to the body indicating DN, pressure class, material, serial number, and certification marks. A complete quality dossier—including material certificates, heat treatment records, and test reports—is provided with each unit .

Valve Details

V. Product Advantages

- Pipeline-Specific Reliability: API 6D compliance ensures the valve meets the unique demands of oil and gas pipelines, including pigging compatibility (full-bore design) and cavity pressure relief. In a 200km natural gas pipeline project, these features reduced maintenance downtime by 35% compared to non-API 6D valves .

- Enhanced Safety in Hazardous Environments: Fire-safe and anti-static features eliminate ignition risks in Zone 1/2 hazardous areas, complying with OSHA (US), ATEX (EU), and GB 3836 (China) regulations. This reduces liability for operators in gas processing plants and refineries .

- Long Service Life and Low Maintenance: WCB carbon steel and 316 stainless steel components resist corrosion and wear, extending the valve’s service life to 8–12 years (vs. 3–5 years for cast iron valves). The modular actuator design allows quick replacement of internal parts without removing the valve from the pipeline, cutting maintenance time by 40% .

- Cost-Effective Versatility: Dual-seal options eliminate the need for separate valves for low- and high-temperature applications. A petrochemical plant reported 20% lower inventory costs after standardizing on TIANYU’s API 6D valve for both crude oil (metal seats) and refined gasoline (soft seats) lines .

- Global Project Compatibility: Compliance with ANSI, BS, and DIN standards enables seamless integration into international projects. A European pipeline contractor avoided $50,000 in custom adapter costs by using TIANYU’s flanged valves, which matched existing ASME B16.5 pipeline flanges .

- Environmental Compliance: Soft seats achieve near-zero leakage (API 598 Class VI), reducing methane emissions by up to 90% compared to conventional gate valves. This helps operators meet stringent environmental regulations such as the EU’s Industrial Emissions Directive .

Application

VI. Product Applications

- Oil and Gas Pipeline Transportation: Deployed in onshore and offshore gathering lines, transmission pipelines, and distribution networks. The full-bore design accommodates pigging for pipeline cleaning, while DBB functionality simplifies leak detection during maintenance . In a Middle Eastern crude oil pipeline, the valve’s corrosion-resistant 316 trim withstood saline soil conditions for 10 years without replacement .

- Petrochemical and Refining: Used in crude oil distillation units, hydrocracking processes, and refined product transfer lines. Metal seats handle high temperatures (up to 425℃) in catalytic reforming systems, while soft seats provide tight shutoff for gasoline and diesel storage . The valve’s fire-safe design complies with refinery safety protocols for flammable liquid service .

- Natural Gas Processing and Storage: Ideal for natural gas treatment plants, LNG terminals, and underground storage facilities. Soft PTFE seats minimize methane leakage, and anti-static features prevent ignition in gas-rich environments . In a US natural gas storage facility, the valve’s worm gear operator enabled manual override during a power outage, avoiding supply disruption .

- Industrial Steam and Water Systems: Used in power generation auxiliary boilers and industrial cooling water loops. Metal seats withstand high-temperature steam (up to 425℃), while the valve’s low flow resistance reduces energy consumption in circulating water systems .

- Chemical Processing: Suitable for non-corrosive to mildly corrosive chemical transfer (e.g., ethanol, ethylene). Optional 316 stainless steel bodies provide enhanced corrosion resistance for acidic media, and PTFE seats prevent chemical contamination .

- Marine and Offshore: Installed in shipboard fuel lines and offshore platform process systems. The epoxy coating resists saltwater corrosion, and RTJ flanged connections ensure leak-tight performance in rough seas .

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025