Specification

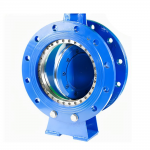

TIANYU Triple Offset Metal Hard-Seal Flanged Butterfly Valve: Reliable Control for Harsh Industrial Conditions

I. Product Technical Overview

II. Core Advantages

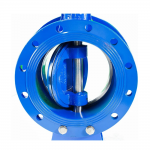

(A) Triple-Eccentric Structure: Zero Friction & Self-Tightening Seal

- Three Offsets:

- Radial offset (stem vs. disc center).

- Axial offset (stem vs. sealing surface centerline).

- Angular offset (sealing surface vs. disc rotation axis).

The disc disengages from the seat within 5° of opening (near-zero friction) and self-tightens during closing, achieving ANSI/FCI 70-2 Class VI bubble-tight leakage (metal-to-metal seal).

- Extended Lifespan: Eliminates seal wear during operation, doubling service life in abrasive media (e.g., blast furnace gas) compared to double-offset valves.

(B) Metal Hard-Seal System: Harsh Condition Adaptability

- Seal Technology:

The disc’s sealing surface uses Stellite 6/21 hard alloy overlay (≥2mm thickness) via plasma cladding, ensuring ≥200MPa bond strength, HRC 45-55 hardness, and resistance to 800℃ short-term heat and particle erosion (e.g., coal dust, slag). - Bidirectional Sealing:

Combines triple eccentricity with metal sealing for bidirectional zero leakage, suitable for high-temperature steam (350℃, 4.0MPa) and corrosive slurries (pH 2-12).

(C) Worm Gear Actuation: High Torque & Precision

- Torque Efficiency:

Worm gearboxes (ratio 1:30–1:60) deliver ≥1000N·m torque (DN300), ideal for large diameters (≤DN1200). Manual operation requires ≤80N·m (API 609 compliant). - Mechanical Lock:

Worm gear drive provides self-locking to prevent disc movement from media backpressure, ensuring system safety (e.g., high-pressure steam lines).

(D) Material Synergy: Corrosion & Strength Balance

| Component | Material | Key Properties |

|---|---|---|

| Body | Ductile Iron (QT450)/WCB | QT450: ≥450MPa tensile, ≥27J impact at -20℃; WCB: ≤425℃, hydrogen embrittlement resistance. |

| Disc | Stainless Steel (304/316L) + Stellite | Stainless steel base for corrosion resistance; hard alloy for wear/heat resistance. |

| Stem | 2Cr13/17-4PH Stainless Steel | Nitrided surface (0.3mm depth), ≥900MPa torsional strength, blowout-proof (API 600). |

| Seal | Metal Hard-Seal (Optional Soft Seal) | Hard seal: ≤425℃; Soft seal (EPDM): ≤180℃, for clean media. |

III. Technical Specifications

| Parameter | Standard | Custom Options |

|---|---|---|

| Size | DN50–DN1200 | Up to DN1600 (engineered evaluation). |

| Pressure Class | PN10–PN63 (1.0–6.4MPa) | ASME Class 150–900 (2.0–15.0MPa, WCB body). |

| End Connection | Flange (GB/T 9113/ANSI B16.5) | Wafer (GB/T 12238), welded. |

| Design Standards | GB/T 12238, API 609 | CE, ATEX (explosion-proof actuation). |

| Testing | GB/T 13927, API 598 | Fire-safe testing (API 607). |

| Actuation | Worm Gear (Manual) | Electric/pneumatic (4-20mA control). |

Product Overview

IV. Manufacturing & Quality

(A) Precision Manufacturing

-

Body Casting:

- Ductile iron: Lost foam casting + annealing (ferrite ≥85%).

- WCB: Resin sand casting + normalizing/tempering (grain size ≥6).

- NDT: 100% UT (WCB) / MT (ductile iron), defects ≤JB/T 6059 Level 2.

-

Disc & Seal Processing:

- Stainless steel disc: 5-axis CNC machining (roundness ≤0.02mm, Ra≤0.8μm).

- Stellite overlay: Plasma cladding (≥2mm thickness, 500-hour salt spray tested).

-

Actuator Assembly:

- Worm gearbox: Precision hobbing (class 6 accuracy, backlash ≤0.05mm).

- Valve testing: 1.5× hydrostatic (30-minute hold), 1.1× helium leak (≤1×10⁻⁴ mbar·L/s).

(B) Quality Assurance

- Traceability: Material heat numbers, CMA reports, and third-party PMI testing.

- Certifications: ISO 9001, API 609, ATEX II 2G Ex db IIC T4 (explosion-proof).

- Warranty: 24-month coverage for manufacturing defects (seal failure, structural deformation).

Valve Details

VI. TIANYU Customization Strengths

- Material Upgrades: Duplex steel (2205), Hastelloy (C276), or Inconel for extreme corrosion/heat.

- Actuation Expansion: Smart electric (Modbus) or pneumatic (positioner) actuators for remote control.

- Seal Flexibility: Switch between metal hard-seal and EPDM/NBR soft-seal (clean media).

- Delivery: 25-day standard lead time, 18-day small-batch custom, 72-hour emergency service.

- Support: Global technical centers provide lifecycle management, 48-hour spare parts, and AR-assisted maintenance.

Application

V. Application Scenarios

(A) Petrochemical: High-Temperature Steam/Oil

(B) Power: Desulfurization & Cooling Water

(C) Metallurgy: Blast Furnace Gas

(D) Municipal: High-Temperature Heating

Our Strengths

Best Quality Industrial Valve Solutions For You

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025