Specification

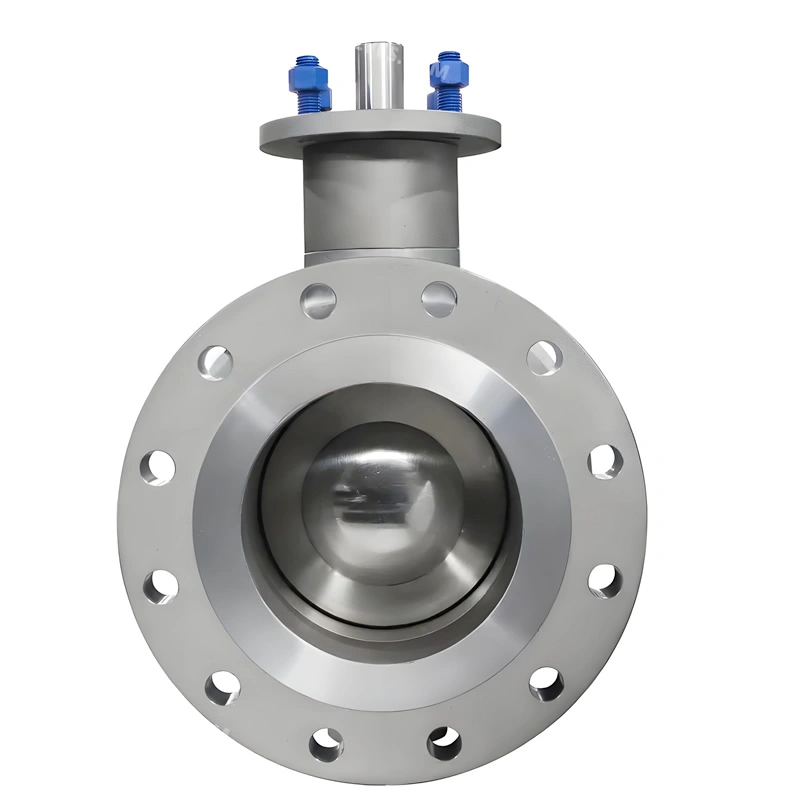

DN100 Class 300 Carbon Steel 2PC Trunnion Top Flange Ball Valve |

|

| Porduct Name | ANSI Class 300 Carbon Steel WCB With Top Flange 2PC Trunnion Mounted Ball Valve |

| Material | Stainless Steel/Duplex steel/Aluminium Bronze/Nickel-aluminum Bronze/Titanium Alloy, etc. |

| Size | 2~16 inch ( DN50~DN400) |

| Port | Full Port/Reduce Port |

| Working Pressure | 150LB/300LB/600LB/900LB/1500LB/2500LB |

| Connection Ends | RF, RTJ, BW,FF |

| Working Temp. | -20ºC~280ºC for soft seat, -196ºC to 600ºC for metal seat |

| Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid |

| Operated | Manual, Gearbox, Pneumatic actuator, Electric Actuator |

| Features | Fire safe, anti-static device |

| Design standard | ASME B16.34,API608,API6D |

| Inspection&Testing | API598 |

| Brand | TIANYU |

| Design & Manufacture standard | API6D |

| Pressure & Temperature standard | ASME B16.34 |

| Face to face dimension standard | ASME B16.10 |

| Ends Connection standard | ASME B16.5 |

| Test & Inspect standard | API598 |

| Fire-safe conform to API 607 | API 607 |

Product Overview

I. Product Overview

II. Key Attribute Parameters

- Size Range: 2″~16″ (DN50~DN400), covering small to medium-diameter pipelines to meet flow requirements in process loops, transmission lines, and equipment interfaces.

- Pressure Rating: ANSI Class 150~900 (PN16~PN150), with Class 300 (5.0MPa) as a common specification, suitable for medium to high-pressure applications.

- Temperature Range:

- Soft seal (RPTFE/PPL): -20℃~280℃, ideal for moderate temperature media.

- Metal seal: -196℃~600℃, adapting to cryogenic or high-temperature environments (e.g., steam, LNG).

- Material Configuration:

- Body & Closure: Carbon steel (WCB, ASTM A216), offering high tensile strength (≥485MPa) for structural integrity; optional stainless steel (CF8/CF8M) for corrosive media.

- Ball & Stem: Carbon steel (A105N+ENP) or stainless steel (F316), with precision-machined surfaces for tight sealing.

- Seal: Soft seal (RPTFE/PPL) for low leakage; metal seal (stainless steel) for high temps and abrasion resistance.

- Connection Type: Flanged (RF/RTJ per ASME B16.5) or butt-weld (BW), ensuring leak-tight integration with pipeline systems.

- Operation: Manual (handwheel), gearbox, pneumatic, or electric actuator, with gear operation reducing torque for large-diameter valves.

- Standards Compliance: Design per API 6D, API 608; pressure-temperature ratings per ASME B16.34; testing per API 598; fire-safe per API 607.

III. Structural Features

- 2-Piece Split Body: Valve body splits into two sections joined by bolts, balancing structural rigidity and ease of maintenance. This design simplifies internal component access (ball, seat, stem) without full disassembly from the pipeline, reducing downtime.

- Trunnion-Mounted Ball: The ball is supported by upper and lower trunnions, distributing pressure loads to prevent deformation under high pressure. This eliminates “ball blowdown” risk, ensuring stable operation in Class 600+ systems with flow surges.

- Top Flange Design: Integral top flange (ISO 5211 standard) facilitates quick actuator mounting, enabling easy upgrades to automated control (pneumatic/electric) without modifying the valve body—ideal for retrofitting manual systems.

- Dual Seal Options: Soft seals (RPTFE) provide bubble-tight shut-off (ANSI FCI 70-2 Class VI) for clean media; metal seals (stainless steel) resist wear from solid particles and high temps, suitable for harsh environments.

- Safety Enhancements: Anti-static device (stainless steel spring) dissipates static (resistance ≤10⁶Ω) to prevent sparks; fire-safe graphite backup seals (API 607) ensure basic shut-off during fire, reducing leakage risks in hazardous areas.

IV. Manufacturing Processes

- Material Preparation: Carbon steel castings (WCB) undergo spectral analysis to verify chemical composition (C≤0.30%, Mn≤1.00%) and ultrasonic testing to eliminate internal defects (cracks, shrinkage). Forged components (stem/ball) are stress-relieved to avoid deformation.

- Precision Machining:

- Ball & Seat: CNC grinders achieve ball roundness ≤0.01mm and surface finish Ra ≤0.8μm; seats are lapped to match ball contours, ensuring uniform contact for tight sealing.

- Body & Flange: CNC lathes machine flange sealing faces to flatness ≤0.05mm, with bolt holes drilled to ±0.1mm tolerance for alignment with pipelines. Top flange is machined to ISO 5211 dimensions for actuator compatibility.

- Assembly & Testing:

- Seats are pre-loaded with Inconel X-750 springs to compensate for thermal expansion, ensuring consistent contact across temperature cycles.

- Each valve undergoes API 598 testing: hydrostatic shell test (1.5×Class pressure for 30 minutes), seat leakage test (1.1×Class pressure with air/water), and 1000+ operation cycles to verify durability.

- Surface Treatment: Carbon steel bodies are sandblasted (Sa 2.5) and coated with high-temperature epoxy paint (dry film thickness ≥80μm) for corrosion resistance; stainless steel components are passivated to enhance rust resistance.

Valve Details

V. Product Advantages

- High-Pressure Stability: Trunnion mounting and 2-piece carbon steel body withstand Class 900 (15.0MPa) pressure, outperforming floating ball valves in high-pressure systems by 40% in service life.

- Flexible Seal Options: Soft seals suit clean, moderate-temp media (e.g., drinking water), while metal seals handle abrasive, high-temp fluids (e.g., crude oil with particulates), expanding application range.

- Easy Installation & Upgrade: Top flange enables quick actuator mounting, allowing seamless transition from manual to automated control—critical for smart factory retrofits.

- Safety Compliance: Fire-safe and anti-static features meet hazardous area requirements (e.g., oil refineries, gas pipelines), reducing operational risks.

- Cost-Effective: 2-piece design balances durability and material efficiency, lowering production costs compared to 3-piece valves while maintaining performance in Class 300+ systems.

Application

VI. Application Fields

- Oil & Gas Industry: Midstream transmission pipelines and downstream refineries, controlling crude oil, natural gas, and refined products under high pressure.

- Industrial Manufacturing: Hydraulic systems, fuel lines, and process loops, where reliable shut-off and easy automation enhance production efficiency.

- Water & Wastewater Treatment: High-pressure water distribution and treatment plant pipelines, with soft seals ensuring contamination-free operation.

- Chemical Processing: Handling non-aggressive chemicals and solvents in reaction systems, with carbon steel resisting mild corrosion.

- Power Generation: Auxiliary systems (fuel oil, cooling water) in thermal power plants, where Class 300 rating and temperature resistance meet operational demands.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025