Specification

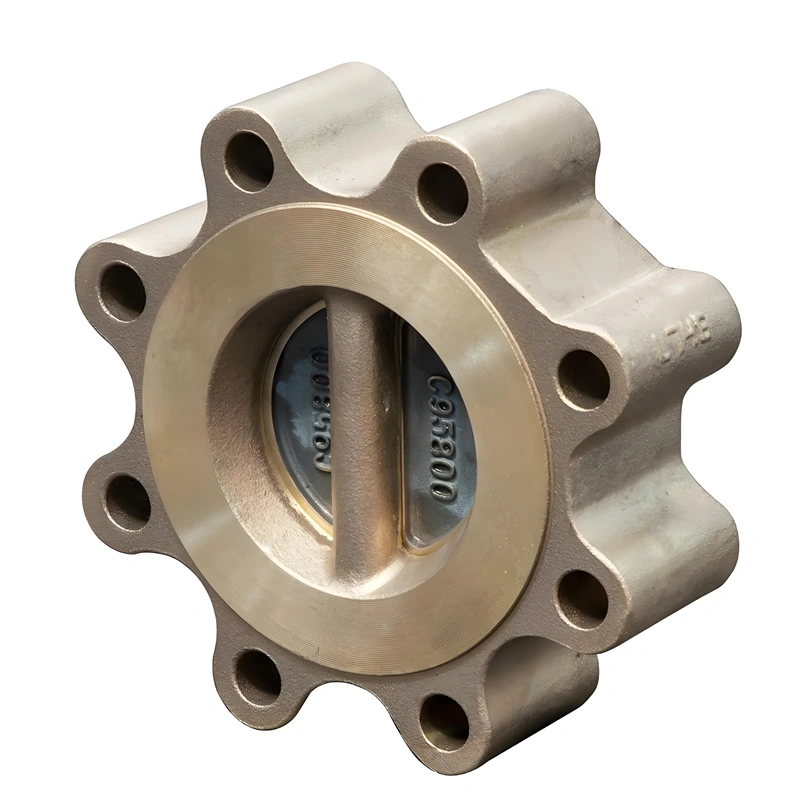

TIANYU C95800 Double-Plate Aluminum Bronze Lug Swing Check Valve

I. Product Overview

II. Key Attribute Parameters

- Size Range: 2″to 60″ (DN50 to DN1500), covering small to large-diameter pipelines, Adapt to everything from precision instrument pipelines to large industrial main pipelines.

- Pressure Class: 150LB to 2500LB (PN16 to PN420), suitable for low, medium, and high-pressure systems, meeting diverse industrial pressure requirements.

- Material Specifications:

- Body & Disc: C95800 aluminum bronze (high corrosion resistance, ideal for marine, chemical, and high-humidity environments); other options include WCB, WC6, CF8 (stainless steel), duplex stainless steel, etc., for different media.

- Sealing: Precision-machined metal-to-metal seals or soft seals (based on medium), ensuring zero leakage.

- Connection Type: Lug-type (flange ends optional), allowing easy installation in any pipeline orientation (horizontal or vertical) without disrupting the entire system.

- Temperature Range: -196℃ to 540℃ (varies by material), adapting to cryogenic and high-temperature media like steam.

- Applicable Media: Water, oil, gas, and corrosive fluids (compatible with different materials for specific media).

- Standards Compliance: Designed per API 594; face-to-face dimensions per ANSI B 16.10; flange dimensions per ANSI B 16.5/16.47; tested per API 598.

Product Overview

III. Feature Description

- Dual-Plate Design: Two symmetric discs swing to open/close, reducing flow resistance compared to single-plate designs. The discs reset quickly to prevent water hammer, protecting pipeline equipment.

- Zero External Leakage: Integral body and precision machining ensure tight sealing, eliminating external leakage—critical for hazardous or high-value media.

- Versatile Installation: Lug-type connection allows installation in any orientation (horizontal, vertical, or inclined), adapting to limited space or complex pipeline layouts.

- Renewable Seals: Split discs and replaceable seals simplify maintenance; worn components can be replaced without replacing the entire valve, reducing lifecycle costs.

- Corrosion Protection: C95800 aluminum bronze resists saltwater, chemicals, and oxidation—ideal for marine, coastal, or chemical processing environments. Internal/external epoxy coating further enhances durability.

IV. Manufacturing Process

- Raw Material Inspection: C95800 aluminum bronze and other materials undergo chemical composition and mechanical property testing to meet standards.

- Rough Machining: CNC cutting shapes the valve body, lugs, and disc blanks, ensuring basic dimensions.

- Precision Polishing: Body inner walls and sealing surfaces are polished to Ra≤1.6μm, reducing flow resistance and ensuring tight sealing.

- Disc & Hinge Processing: Discs are machined to strict tolerances; hinges (pins) are heat-treated for wear resistance, ensuring smooth swing motion.

- Assembly: Discs, pins, and seals are assembled with precision alignment, testing swing flexibility to ensure quick response to flow changes.

- Pressure Testing: Each valve undergoes API 598 tests—hydrostatic shell test (1.5× nominal pressure) and seat leakage test (1.1× nominal pressure)—to verify no leakage.

Valve Details

V. Product Advantages

- Water Hammer Prevention: Dual plates close rapidly (faster than single-plate valves) to minimize pressure surges, extending pump and pipeline service life.

- Cost Efficiency: Lug-type design reduces installation time; renewable components lower maintenance costs. Its long lifespan (10+ years in normal use) reduces replacement frequency.

- High Reliability: Compliant with API/ANSI standards, ensuring compatibility with global pipeline systems. Stable performance in extreme temperatures/pressures minimizes unplanned downtime.

- Corrosion Resistance: C95800 aluminum bronze outperforms carbon steel in harsh environments, reducing corrosion-related failures—ideal for offshore, chemical, or wastewater applications.

Application

VI. Product Applications

- Marine & Offshore: Saltwater cooling systems, ballast pipelines—resists seawater corrosion to prevent valve failure.

- Chemical Processing: Acid/alkali transfer lines, ensuring no backflow of corrosive media to protect reactors and pumps.

- Power Generation: Steam pipelines in thermal power plants; prevents condensate backflow into boilers, maintaining system efficiency.

- Metallurgy & Mining: Slurry or cooling water pipelines; dual-plate design resists abrasion, ensuring reliable operation in high-solids media.

- Water & Wastewater: Municipal water supply or sewage systems; prevents backflow to avoid contamination or pump damage.

TIANYU C95800 Double-Plate Lug Swing Check Valve (2″-60″, 150LB-2500LB) suits water, oil, gas, -196-540℃. Features dual plates, zero leakage, versatile installation, corrosion resistance. Applies to marine, chemical, power sectors. Customizable in material and size for specific needs.

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025