Specification

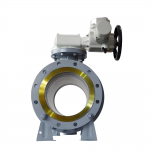

TIANYU 12″ Class 150 Full Bore Two-Piece Trunnion Mounted Ball Valve: Precision Control for Industrial Fluid Systems

I. Product Overview

II. Core Advantages

(A) Two-Piece Design: Compact & Serviceable

- Symmetrical Forged Construction:

The two-piece body, joined by high-strength bolts, ensures coaxiality within 0.05mm. This design reduces weight by 15% compared to three-piece valves, saving installation space while enabling 40% faster maintenance via unilateral flange disassembly. - Dual-Seal Redundancy:

Metal-to-metal body joints with flexible gaskets provide secondary sealing, meeting ASME B16.34 requirements for high-pressure applications.

(B) Trunnion-Mounted Ball with Spring-Loaded Seats

- Bidirectional Block & Bleed (DBB):

Spring-loaded RPTFE seats achieve zero leakage (ANSI/FCI 70-2 Class V) in both flow directions. A vent/drain port prevents cavity overpressure, enhancing safety in critical applications. - Wear Compensation:

Spring-loaded seats maintain sealing integrity even with up to 0.2mm of wear, extending service life by 30% and reducing maintenance costs.

(C) Full Bore Flow Path: Efficiency Unleashed

- Equal Diameter Flow:

The unobstructed bore (≥300mm) matches pipeline diameter, minimizing pressure drop (Cv ≥1,200) and turbulence. Ideal for high-flow applications like gas transmission and refinery feed lines. - Smooth Internal Surface:

Precision-machined internals (Ra ≤1.6μm) prevent media accumulation, reducing clogging risks and ensuring long-term reliability.

(D) Intelligent Electric Actuation System

- High-Performance Actuator:

IP66-rated intelligent actuator with 4-20mA/Modbus communication, ±1° positioning accuracy, and ≤15-second full-stroke time. Built-in overload protection and temperature compensation ensure stable operation in harsh environments. - Manual Override:

Worm gear handwheel with 1:30 ratio and ≤80N·m torque (API 609 compliant) enables emergency operation during power outages. - Real-Time Monitoring:

Integrated position sensors and fault diagnostics provide remote status updates, enabling predictive maintenance and reducing downtime.

(E) Material Excellence

| Component | Material | Key Properties |

|---|---|---|

| Body | WCB Carbon Steel | Tensile strength ≥485MPa, Charpy V-notch impact energy ≥27J at -29°C |

| Ball | A105+ENP Coating | Surface hardness HV500-600, 3x improved wear resistance, salt spray tested |

| Seats | RPTFE | Compression set ≤10% (150°C ×72h), resistant to hydrocarbons and aqueous media |

| Stem | 17-4PH Stainless Steel | Nitrided surface (0.3mm depth), torsional strength ≥900MPa, blowout-proof design |

III. Technical Specifications

| Parameter | Standard Rating | Customization Options |

|---|---|---|

| Size | 12″ (DN300) | 8″-24″ (DN200-DN600, custom sizes available) |

| Pressure Class | Class 150 (PN2.0MPa) | Class 300/600 (PN5.0/10.0MPa, upgraded design) |

| End Connection | Flange (ANSI B16.5 RF) | Butt-weld (ANSI B16.25), socket-weld |

| Design Standards | API 608, ASME B16.34 | CE, ATEX (explosion-proof options) |

| Testing | API 598 (1.5x hydrostatic) | Fire-safe testing (API 607) |

| Actuation | Electric + Manual Override | Pneumatic/hydraulic actuators available |

Product Overview

IV. Manufacturing & Quality Assurance

(A) Precision Manufacturing Process

-

Two-Piece Body Fabrication:

- Forged and CNC-machined components joined via dowel pins and high-strength bolts, ensuring ≤0.05mm coaxiality.

- WCB bodies undergo normalizing + tempering for uniform mechanical properties. NDT includes 100% RT (ASME SE-164 Level B) and MT (ASME SE-709) with defects ≤ASTM E446 Level 2.

-

Ball & Stem Machining:

- A105 forged balls machined to ≤0.02mm roundness with Ra ≤0.8μm sealing surfaces.

- ENP coating (≥0.05mm thickness) provides corrosion resistance exceeding 500-hour salt spray testing.

- Stems feature cold-rolled threads (6g accuracy) and nitrided surfaces (0.3-0.5mm depth).

-

Seat Assembly & Testing:

- Hydraulically preloaded RPTFE seats with ≤0.05mm sealing clearance. Each valve undergoes 1.5x hydrostatic testing (30-minute hold) and helium leak testing (≤1×10⁻⁴ mbar·L/s).

- Sampled valves complete 100,000 cycle life testing with ≤15% torque decay and Class V sealing retention.

(B) Quality Traceability & Certification

- Material Certification: Furnaces records, CMA-certified chemical analysis, and third-party PMI testing available.

- System Compliance: ISO 9001, API 608, ATEX II 2G Ex db IIC T4 (for explosion-proof actuators).

- Warranty: 24-month comprehensive warranty with unconditional replacement for manufacturing defects.

Valve Details

VI. TIANYU Customization Capabilities

- Material Upgrades: CF8M stainless steel, duplex steel for corrosive media.

- Sealing Solutions: Stellite hard seats for high-temperature/abrasive applications.

- Actuation Expansion: Pneumatic/hydraulic actuators, enhanced explosion-proof ratings.

- CFD Optimization: Flow simulation for custom bore designs and reduced turbulence.

- Rapid Delivery: 22-day standard lead time, 15-day expedited service for small batches.

- Global Support: Six technical centers providing lifecycle management, 48-hour spare parts delivery, and AR-assisted maintenance.

Application

V. Product Application Scenarios

(A) Petrochemical Industry

(B) Natural Gas Transmission

(C) Power Generation

(D) Municipal Energy

RELATED

-

High Temperature/Pressure 304 Stainless Steel Resistant Manual Power Forged Three Piece Flanged Floating Ball Valve

TIANYU 304 Stainless Steel Flanged Floating Ball Valve: Corrosion-Resistant Full-Port Flow Control Solution for Industrial, Sanitary, and Municipal Me…

BALL VALVE 11/03/2025 -

API ANSI 2in-16in DN50-DN400 PN10 PN16 CF8M Pneumatic Flanged Floating Ball Valve

TIANYU CF8M Pneumatic Flanged Floating Ball Valve: 2in-16in (DN50-DN400) PN10-PN16 API/ANSI Class Corrosion-Resistant Flow Control Solution for Indust…

BALL VALVE 11/01/2025 -

Large-Diameter DN1400 CLASS150 WCB SS Triple Eccentric Metal-Sealed Hard Seal Butterfly Valve

TIANYU DN1400 (56″) CLASS 150 WCB Hard Seal Butterfly Valve: Triple Eccentric Metal-Sealed Flanged Valve for Large-Diameter Industrial Media wit…

BUTTERFLY VALVE 10/30/2025 -

PN16 Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static SS Ball Valve

TIANYU Stainless Steel Floating Ball Valve: Full Port 2PC Flange-Connected Valve with Fire-Safe & Anti-Static Design for Oil, Gas, and Industrial …

BALL VALVE 10/29/2025 -

High-Performance DN80 Class 150 WCB Soft-Sealed Lug-Type Double Eccentric Butterfly Valve

TIANYU 3” Class 150 WCB lug-type double eccentric butterfly valve is a technologically advanced flow control device engineered to address the challeng…

BUTTERFLY VALVE 10/25/2025 -

DN125 PN16 CF8M Stainless Steel Lug-Type Butterfly Valve with PTFE Lining Concentric Line Butterfly Valves

TIANYU DN125 PN16 CF8M stainless steel lug-type butterfly valve is a precision-engineered flow control device designed to address the challenges of ha…

BUTTERFLY VALVE 10/25/2025